Mic 6 tooling plate

Re: Mic 6 tooling plate

I should figure out how the work the height offsets....any word on if 6061 is good enough for 1 print?

Re: Mic 6 tooling plate

If it works for 1 print it'll work for a lot -- the downside to 6061 is that it changes shape as it heats up, whereas MIC6 doesn't. It doesn't get consumed in the printing process.

Custom 3D printing for you or your business -- quote [at] pingring.org

Re: Mic 6 tooling plate

Thanks insta. I wasn't sure if heating it once verses cyclic heating for multiple prints would make a difference. MIC6 is a little expensive to buy a new plate for every print...

Re: Mic 6 tooling plate

Why are you consuming aluminum plates per print?

Custom 3D printing for you or your business -- quote [at] pingring.org

Re: Mic 6 tooling plate

The part will be left on the plate. I am trying to take advantage on the print already being located on the plate when it is printed.

Re: Mic 6 tooling plate

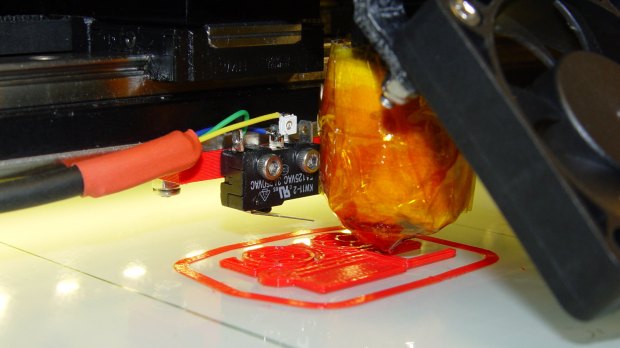

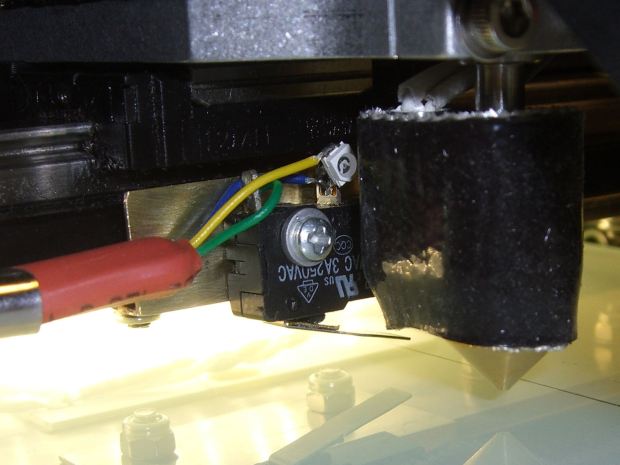

If you're up for an adventure, just move the Z-axis switch to the X-axis gantry where it directly senses the top of whatever plate you're using:Alloy wrote:I will be switching between the .125" glass and .250" aluminum

http://softsolder.com/2013/10/14/makerg ... in-switch/

That post gives a rundown of the G-Code tweaks required to make homing work; for obvious reasons, you must move the nozzle off the platform before homing the Z axis.

As a side effect, that switch completely eliminates all the dinking around with Z stop screws and nuts and offsets and stuff like that. Swap plates all you want, your prints start with the correct Z=0 position every time. Adjusting the Z=0 point requires changing one number in the startup G-Code to get exactly the difference you expected.

The V4 nozzle sits slightly higher and required a bit more tweaking, but it's the same general idea:

http://softsolder.com/2015/03/10/makerg ... is-switch/

The New Shiny seems to be a proximity sensor that does much the same thing, but they don't work on glass...

Re: Mic 6 tooling plate

Ed, I would love to see a picture of your "Frankenprinter".

You really should do up a thread in the Modifications section with pics of all your mods.

(From a science standpoint, it would be invaluable, and we could point people to it when they want to try something out-of-the-box.)

You really should do up a thread in the Modifications section with pics of all your mods.

(From a science standpoint, it would be invaluable, and we could point people to it when they want to try something out-of-the-box.)

Re: Mic 6 tooling plate

I want to see what happens if I visit Ed, with my entropy field in tow.Jules wrote:Ed, I would love to see a picture of your "Frankenprinter".

You really should do up a thread in the Modifications section with pics of all your mods.

(From a science standpoint, it would be invaluable, and we could point people to it when they want to try something out-of-the-box.)

I'm actually curious what happens if I visit MakerGear themselves. My guess is one of the big 3-phase transformers outside blows when I walk in.

Custom 3D printing for you or your business -- quote [at] pingring.org

Re: Mic 6 tooling plate

Better not try it......i want that Auto-Level one of these days!insta wrote:.......I want to see what happens if I visit Ed, with my entropy field in tow.

I'm actually curious what happens if I visit MakerGear themselves. My guess is one of the big 3-phase transformers outside blows when I walk in.

(who was that Peanuts character that had the little cloud following him around everywhere? No wait, maybe it was Dogpatch?)

Got it! Joe Btfsplk

Re: Mic 6 tooling plate

haha insta, rick will see you coming and as you walkup to the building all the doors shut and you hear dead bolds sliding on the inside..lmao!