Build Plate Corner Mounts

- pyronaught

- Posts: 684

- Joined: Mon Dec 01, 2014 8:24 pm

Build Plate Corner Mounts

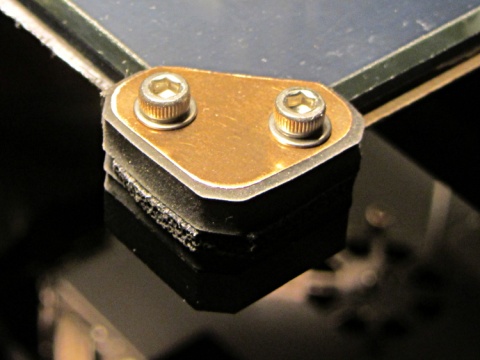

Anyone ever have problems with the build plate not seating flat using the rubber corner mounts? I could not get mine to make contact in all four corners perfectly, thus it would rock if you pressed in the rear right corner. Because of this I could shift it out of level when scraping the glass or pulling a part. I replaced the rubber squares with segments cut from 1/8" thick steel flat bar and the problem went away. I kept the rubber corner brackets and only replaced the rubber squares that the build plate sits on. It is very stable with the metal contact points now.

Experience is what you get when you didn't get what you wanted.

Re: Build Plate Corner Mounts

so if the glass wasnt in place, was the aluminum heater rocking on the 4 corners or was the glass rocking on the heater plate? judging by your post i am going to say the heater plate was rocking on the rubber?

- pyronaught

- Posts: 684

- Joined: Mon Dec 01, 2014 8:24 pm

Re: Build Plate Corner Mounts

yes, it was the heater plate rocking. The glass was solid against the plate.

Experience is what you get when you didn't get what you wanted.

Re: Build Plate Corner Mounts

mine never had a problem and i dont recall anyone over the past year and a half ever posting that issue....anything is possible though. from the heat the rubber usually settles into the plate so i would think it would have a nice fit.

Re: Build Plate Corner Mounts

That seemed like a Bad Thing for overall print consistency, so I put the heater plate up on balls:jimc wrote:from the heat the rubber usually settles into the plate

http://softsolder.com/2013/07/16/makerg ... ort-balls/

The rubber still insulates the corner and stabilizes the plate horizontally. The balls align the heater to the support spider, which turned out to be exactly flat.

The next step added corner clips that hold the glass+heater assembly in position:

http://softsolder.com/2013/07/18/makerg ... ner-clips/

Without the bulldog clips, the nozzle had four fewer collision targets...

Re: Build Plate Corner Mounts

thats a pretty good idea with the ball in there. it looks like it was just the right dia. after a year and a half of heat my rubber got rock hard and brittle. it just crumbled in my hand. i ended up printing new ones in ecoflex. i didnt have any rocking on the corners but here is what i did to get rid of using clips and take out any movement. of course this prob wont work with glass because the glass is too thin. i just drilled a hole in the corner of it. this doesnt actually tighten down on the plate at all, its only and adjustment to take out any movement. the screws just touch the corners. i only needed to do it on the front two. those two keep the plate pushed against the rear 2 corners. i like these because they dont stick above the plate and get in the way during the stock homing sequence.

- pyronaught

- Posts: 684

- Joined: Mon Dec 01, 2014 8:24 pm

Re: Build Plate Corner Mounts

I guess one of my rubber squares was either thicker than the others or it wasn't level. The balls are a nice idea, by supporting at single points you don't even have to worry about how level the pads are. Seems like they would cut back on heat transfer to the spider too. I was concerned about the added rate of heat transfer when switching from the rubber to the steel, but it appears that the spider gets hotter the closer to the center you get so apparently it heats up more from heat radiating from the bottom of the platform heater than it does from heat conducted down from the corners.

Experience is what you get when you didn't get what you wanted.