wmgeorge wrote:the Z Switch Mechanical switch stop and its adjustment

Point is, if you set the offset using a G92 Z... in the start G-Code, then you don't need

any mechanical adjustment, at least after you set the switch to trip within a few millimeters of the desired position.

In fact, I moved that switch to the X-axis gantry. It trips when the platform is about 2 mm higher than the nozzle (so, obviously, the startup code must move the nozzle off the platform before homing Z!) and I use G92 to set the Z=0 position exactly at the nozzle tip. No mechanical adjustments at all: no locking screws, no thumbscrews, nothing!

As long as the nozzle remains at the same offset from the switch trip position (which it will, if you don't remove the hot end), the G92 offset remains constant. I can (and have!) re-aligned the platform without doing anything else, because the switch detects the glass when it's at the same position relative to the nozzle.

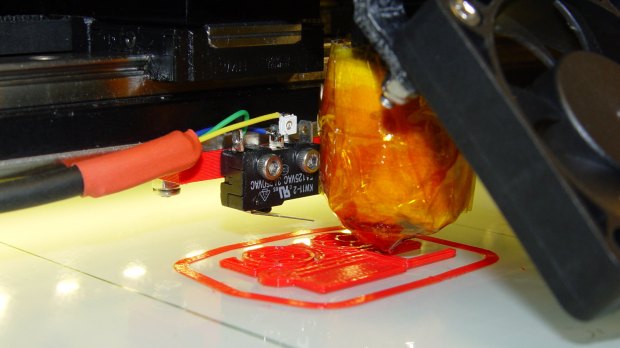

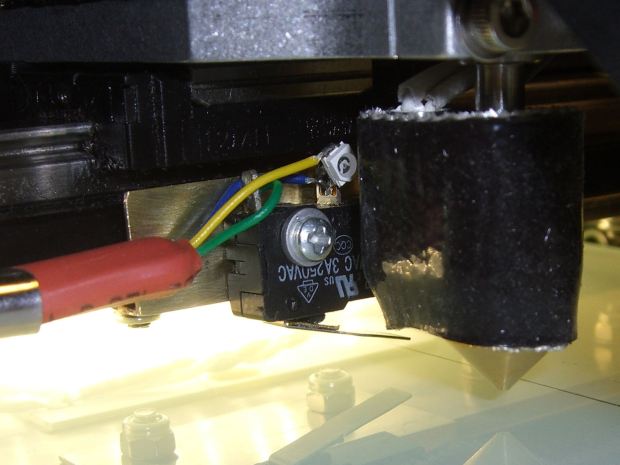

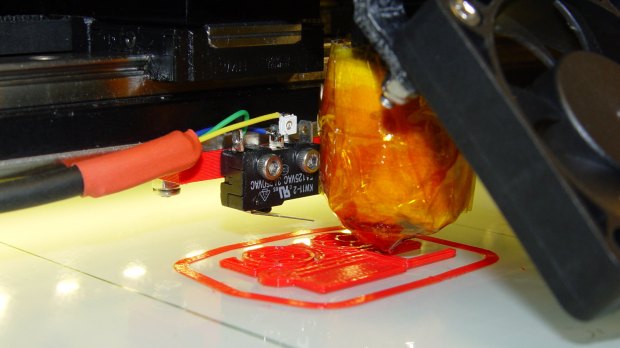

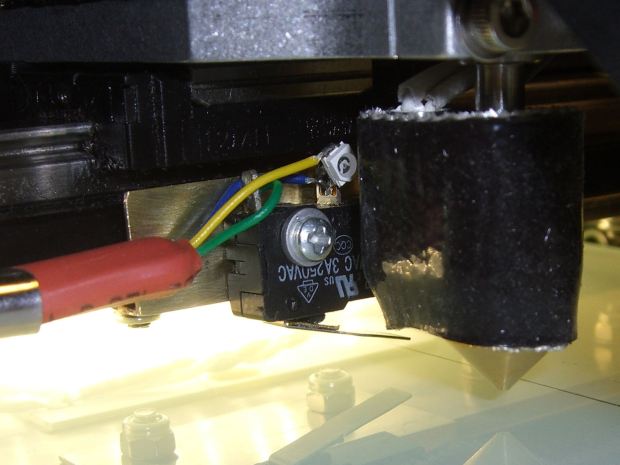

The first pass with the V3 hot end had the switch on a printed block:

http://softsolder.com/2013/10/14/makerg ... in-switch/

The V4 hot end called for an actual metal bracket:

http://softsolder.com/2015/03/10/makerg ... is-switch/

Measure the offset once, set the G92 Z value, done!

Simple, easy, cheap. Oddly, nobody else likes it... [sigh]

(I might just do it to do it now though)