innkeeper wrote:if the build plate isn't flat / warps when heated

Misalignment is the print killer: the need to maintain the Z-axis position closer than ±0.1 mm across the entire expanse of the platform rules out essentially all the cheap, easy, convenient, simple implementations. Conversely, ignoring that tolerance leads to a whole bunch of stuff that produces nothing but headache...

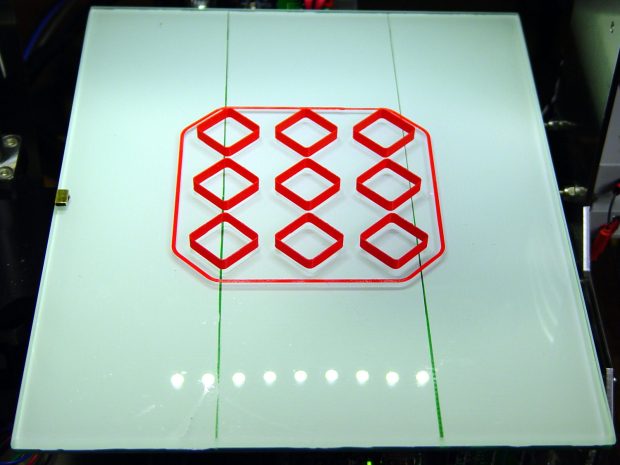

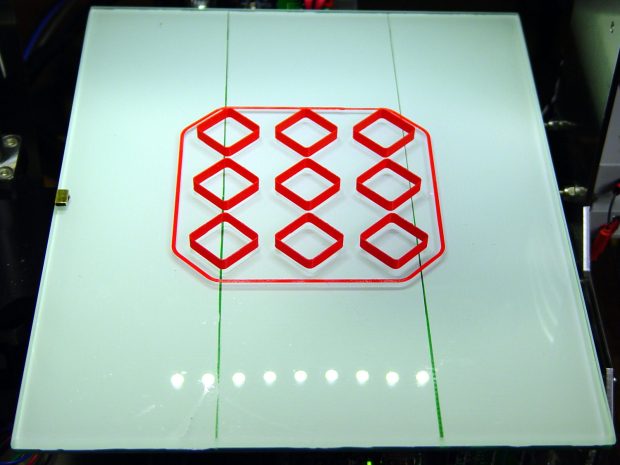

For example, I've been using a hotrod platform that consists of a PCB heater bonded to a borosilicate glass slab. The whole thing mounts to the Y-axis stage through the three alignment screws: no spider, no clamps, just a dead-flat piece of hot glass. This is an early picture, before I finished relocating the platform height switch:

https://softsolder.com/2013/10/11/maker ... hermistor/

The guy who built that recently proposed bonding a silicone heater to the M2's original heat spreader (the anodized 1/8 inch = 3 mm aluminum sheet with the Makergear logo), with a slice of PEI bonded to the top. Turns out that

his sheet is as flat as he can measure it, while

mine has a 0.5 mm trough along the middle; the edges along the +X and -X sides of the sheet have a distinct upward bend. We can't tell how much the sheet will warp when heated, but I'm certain mine won't magically become good enough to be useful.

So, replacing heavy glass with lightweight aluminum will certainly reduce the heating time and, with bit of luck, his platform might actually be flat enough on his M2. However, my version of

the same materials definitely won't work on my M2. You can't see that 0.5 mm warp without a known-good straightedge, but that much Z-axis error will destroy any print.

Bonding a PCB heater to a sheet of PEI

might work in an M2, but I expect it won't produce stable, accurate results.