The place to discuss filament...

-

ednisley

- Posts: 1188

- Joined: Fri Apr 11, 2014 5:34 pm

- Location: Halfway up the Hudson

-

Contact:

Post

by ednisley » Thu Mar 26, 2015 1:39 pm

pyronaught wrote:no way of printing that where the layers run in the ideal direction

Think "assembly" rather than "miracle": print the tabs separately, solvent-bond them in place, and move on.

If you do it right, the joint will be at least as strong as the base material. Perhaps you can design a socket for the tab to provide some reinforcement. If that lets you re-orient the rest of the lens for better results, it might be a net win, even after manual assembly.

-

pyronaught

- Posts: 684

- Joined: Mon Dec 01, 2014 8:24 pm

Post

by pyronaught » Thu Mar 26, 2015 3:35 pm

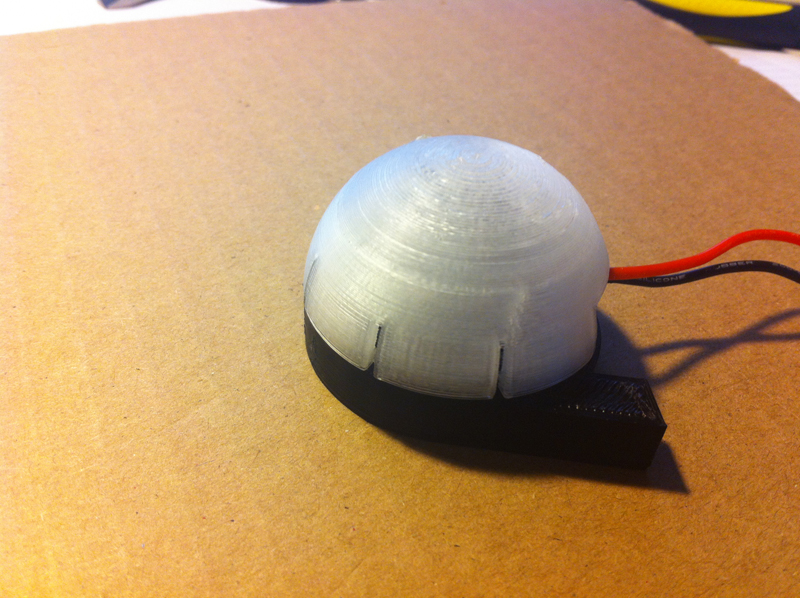

I need to make lots of these though, so they need to be fast and easy. One UFO requires at least six of them, preferably more. I want to be able to just run off a plate full of them over night and have plug-n-play parts the next day. What I wound up doing is increasing the wall thickness from 1.5 to 2mm, then using a manual extrusion width of .5mm to insure no air gaps between extrusion lines. This created a tougher tab, then I opened up the lock rim diameter a little to loosen the fit so that the tabs don't have to flex as much when snapping it on. So the ABS version is working pretty good now, but it will be interesting to compare the PETG version when the filament gets here.

- dome_light1.jpg (419.08 KiB) Viewed 14678 times

- dome_light2.jpg (461.75 KiB) Viewed 14678 times

Experience is what you get when you didn't get what you wanted.

-

pyronaught

- Posts: 684

- Joined: Mon Dec 01, 2014 8:24 pm

Post

by pyronaught » Thu Mar 26, 2015 4:23 pm

Oh yeah, this is going to be good! Imagine a ring of these things up in the sky flying around and hovering at night

- dome_light3.jpg (299.82 KiB) Viewed 14673 times

Experience is what you get when you didn't get what you wanted.

-

ednisley

- Posts: 1188

- Joined: Fri Apr 11, 2014 5:34 pm

- Location: Halfway up the Hudson

-

Contact:

Post

by ednisley » Thu Mar 26, 2015 7:23 pm

pyronaught wrote:so they need to be fast and easy

Looks like you

definitely needed a miracle for those, then figured out how to get one.

3D printing FTW!

-

pyronaught

- Posts: 684

- Joined: Mon Dec 01, 2014 8:24 pm

Post

by pyronaught » Thu Mar 26, 2015 10:13 pm

I've found it's not really an issue of layer bonding strength but rather air gaps between the extrusion lines that cause the easy breaks. It's like the phone book trick where you rip one page at a time instead of all pages at once-- the wall strength is only as strong as a single extrusion width when there are gaps between them. Even when the extrusion lines butt up against each other, you still have voids where they curve around at the top and bottom. You have to increase the extrusion width manually to get the lines to squish up against each other so that the voids are squeezed out between them. I'm using an extrusion multiplier of 1.0 with a manual extrusion width of .56 and the tabs are substantially stronger than with my normal settings of .95 and .42 respectively. These settings have to be dialed in for a specific wall thickness, which is 2mm in my case. Transparency also seems to increase a tiny amount with the better layer fills too, probably because the reduction in air voids result in less refraction due to less medium changes as the light passes through. I guess an absolutely perfect fill would be 100% clear, so the opaque fills made from clear filament shows just how far from perfect this type of printing is.

Experience is what you get when you didn't get what you wanted.

-

jimc

- Posts: 2888

- Joined: Wed Apr 09, 2014 11:30 pm

- Location: mullica, nj

-

Contact:

Post

by jimc » Thu Mar 26, 2015 10:19 pm

when printing petg you will see a big clarity difference as you increase temp and extrusion amount.

-

pyronaught

- Posts: 684

- Joined: Mon Dec 01, 2014 8:24 pm

Post

by pyronaught » Fri Mar 27, 2015 3:25 am

I noticed higher temps help with ABS too. I got the ABS dome light cover to where the tabs can take a fair amount of force before breaking off-- enough force that you wouldn't accidentally break one off unless you were trying to. Here's the key params:

extruder temp: 260C

print speed: 3000 mm/min

extrusion multipler: 1.0

Extursion width: .56mm

coast: 1mm

wipe: 5.5mm

infill 100%

There's still lines through the break face though, indicating that there are still voids. I can minimize voids, but can't seem to get rid of them entirely. Where the plastic breaks the lines are white, while the lines where the voids were are the color of the plastic. Weak settings will show thing white lines and wider color lines, while strong settings will have thick white lines and thin color lines. The ideal settings would result in one big fat white line with no color lines at all, but I could never get there.

Experience is what you get when you didn't get what you wanted.

-

pyronaught

- Posts: 684

- Joined: Mon Dec 01, 2014 8:24 pm

Post

by pyronaught » Fri Mar 27, 2015 9:25 pm

jimc wrote:when printing petg you will see a big clarity difference as you increase temp and extrusion amount.

What settings do you use for PETG? I got some clear PETG from Gizmo Dorks today and ran the slotted dome test with the same settings shown above for the ABS with the only difference being the extruder temp being set to 240 instead of 260. The resulting part was even more fragile than the worst of any ABS test I tried. I could even crush the dome itself after all the tabs easily broke off, which I could never do with ABS. The print itself was smooth and looked better than the ABS domes, bridged nice, stuck to the platform well, responded well to ooze control... but the structural integrity was just total crap. I could even take the broken off tabs and break them apart into smaller pieces pretty easily, which I could never do with the ABS. Given that I'm already printing slightly above the highest recommended temp with higher amounts of extrusion, I don't know what else to try. It just appears that layer adhesion with this stuff is very poor, about the same as what the PET+ was.

Experience is what you get when you didn't get what you wanted.

-

insta

- Posts: 2007

- Joined: Tue Sep 16, 2014 3:59 am

Post

by insta » Fri Mar 27, 2015 9:35 pm

You simply have to print it hotter, which you might not be able to do if you have a V3b hotend.

Custom 3D printing for you or your business -- quote [at] pingring.org

-

pyronaught

- Posts: 684

- Joined: Mon Dec 01, 2014 8:24 pm

Post

by pyronaught » Fri Mar 27, 2015 10:22 pm

I just printed it at 260 and it was a lot stronger. About the same as the ABS at that same temp, but it printed cleaner and was more transparent. I do have the V3b hot end, but it can get to 260.

Is the problem that the vb3 can't get as hot as whatever the other option is, or does bad things start to happen beyond a certain temp?

Experience is what you get when you didn't get what you wanted.