Solvent Bonding

- Mark the Greater

- Posts: 124

- Joined: Mon Jul 27, 2015 8:27 pm

- Location: Brookfield, IL

Solvent Bonding

I am specifically looking for the best way to bond PETG. However, I think it would be good to have a quick reference thread for what works best for all materials.

Any thoughts? What do you use and what's your setup?

Any thoughts? What do you use and what's your setup?

Love Always,

MtG

MtG

Re: Solvent Bonding

This thread is a great idea.

WELD ON #4 Acrylic Solvent Cement works great for PLA. Sold at Port Plastics for about $9 for 1 pint. Buy the hypodermic applicator bottle too.

WELD ON #4 Acrylic Solvent Cement works great for PLA. Sold at Port Plastics for about $9 for 1 pint. Buy the hypodermic applicator bottle too.

Re: Solvent Bonding

Weld On #4 also works for PETG. Acetone works for ABS. I prefer using actual hypodermic needles for better control, if you can get them.

Re: Solvent Bonding

Isn't WELD-ON seriously nasty stuff though? Like need a respirator nasty?

-

CCVirginia

- Posts: 73

- Joined: Thu May 28, 2015 7:31 pm

Re: Solvent Bonding

I tried Weld-on with PETG, didn't seem to bond well. It was just a quick test, perhaps I didn't do it right. I was able to pull it apart without much trouble. I would also like to be able to bond PET.

One reason I have been trying to make friends with ABS is to be able to bond it.

One reason I have been trying to make friends with ABS is to be able to bond it.

Re: Solvent Bonding

Weld-on #4 contains Methylene Chloride, which can be pretty nasty. But it's not like Testor's model cement is good for you. Acetone is one of the least noxious solvents, but you should be okay with the Methylene Chloride with a decent amount of ventilation. If you want to maximize the nastiness, get a full bottle of Methylene Chloride and boil it into a vapor to give your prints a nice shiny surface. It works really well, but when I do it, I make sure I set up everything outside the house, and watch it from inside while it's boiling.Bratag wrote:Isn't WELD-ON seriously nasty stuff though? Like need a respirator nasty?

I've had variable results. I've noticed that the Weld-on #4 evaporates extremely fast; for that reason, if you apply it to just one surface and press two pieces together, it may not be a good bond. But it definitely makes the PETg surface get sticky.CCVirginia wrote:I tried Weld-on with PETG, didn't seem to bond well. It was just a quick test, perhaps I didn't do it right.

Re: Solvent Bonding

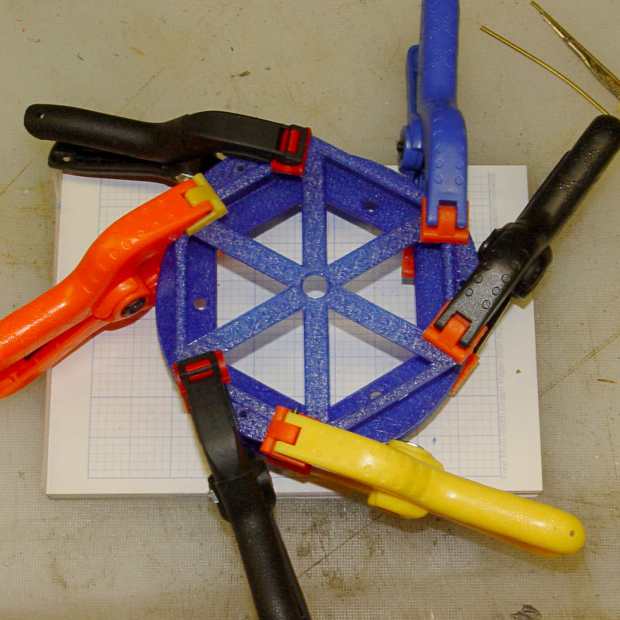

I set alignment pins with a drop of #4 in each hole, dunk the filament, ram it into the holes on one side of the joint and cut the pins to length, spread #4 on both surfaces, pause for a moment, refresh the #4 on surfaces and holes, slap the parts together, and apply Too Many Clamps.Tim wrote:Weld-on #4 evaporates extremely fast

http://softsolder.com/2015/09/17/victor ... rd-holder/

Making a good joint seems to require giving the solvent enough time to bite in, adding more solvent to ensure the surfaces have softened, mashing the parts together with enough force that they become one, then letting the joints alone for at least a few hours. There's not much time to waste before setting the clamps, but using enough solvent makes it do-able.

After that, they're pretty nearly as strong as the PETG on both sides; I can't break them apart with any practical amount of force.

Re: Solvent Bonding

Oh, yes, and I always use the Ed Nisley alignment pin technique! For one thing, regardless of the method you use to apply the solvent, the pins add critical support so that the solvent bond doesn't even get stressed all that much. I've had great success with alignment pins plus superglue, which has no shear strength at all. The alignment pins absorb all the shear force.ednisley wrote:I set alignment pins with a drop of #4 in each hole

Re: Solvent Bonding

ok the proper way to use weld on or methylene chloride is to assemble the parts then you run the needle over the seam and since its thinner than water it wicks into the joint, filling it. thats all you need to do. you are not supposed to apply it then put the parts together. its no different when gluing plexiglass. i used to build aquariums a long time ago and this is how you get that perfect clear and air bubble free seam.

Re: Solvent Bonding

Do you have to clamp it after you let it wick in? (How long does it take to set?)