The official subforum for discussion of the installation and use of the official M2 Dual Extruder upgrade.

-

Ronnien55

- Posts: 60

- Joined: Mon Dec 08, 2014 2:50 am

- Location: Holly Springs NC

Post

by Ronnien55 » Tue Feb 17, 2015 7:59 pm

insta wrote:Ronnien55 wrote:anyone have any good retraction settings. Would like to clean up the part

You gotta retract the bejesus out of NinjaFlex. Do like 6mm @ 60mm/sec, and 250mm/sec travel moves.

I am using simply3D I have adjusted ooze control to: 6mm@3600mm/min, when you say moves are you talking x/y and z movement? My print speed is 1200 mm/min and all underspeeds are set to 100 percent. I am currently running X/Y at 3600 mm/min and Z is 1200mm/min

-

insta

- Posts: 2007

- Joined: Tue Sep 16, 2014 3:59 am

Post

by insta » Tue Feb 17, 2015 8:18 pm

You're right, you have to print slowly, but because it oozes so much you need fast travel (non-printing) moves. Sorry, I use slic3r primarily, which has the same concepts but totally different nomenclature than S3D

The Z speed isn't very important. I use 20mm/sec (1200mm/min) for all my printing moves with no underspeed as well, and getting great results. The faster you retract and whip the print head to the next location (travel speed & retract speed/distance), the cleaner your models will be.

Custom 3D printing for you or your business -- quote [at] pingring.org

-

Ronnien55

- Posts: 60

- Joined: Mon Dec 08, 2014 2:50 am

- Location: Holly Springs NC

Post

by Ronnien55 » Tue Feb 17, 2015 11:08 pm

insta wrote:You're right, you have to print slowly, but because it oozes so much you need fast travel (non-printing) moves. Sorry, I use slic3r primarily, which has the same concepts but totally different nomenclature than S3D

The Z speed isn't very important. I use 20mm/sec (1200mm/min) for all my printing moves with no underspeed as well, and getting great results. The faster you retract and whip the print head to the next location (travel speed & retract speed/distance), the cleaner your models will be.

My latest print is cleaner, increased temp to 250c. I still see some retract bumps and will increase the X/Y a little more to see if i can get it a little smoother. thanks for your invite it has help tremendously.

-

Ronnien55

- Posts: 60

- Joined: Mon Dec 08, 2014 2:50 am

- Location: Holly Springs NC

Post

by Ronnien55 » Tue Feb 17, 2015 11:27 pm

Ronnien55 wrote:insta wrote:You're right, you have to print slowly, but because it oozes so much you need fast travel (non-printing) moves. Sorry, I use slic3r primarily, which has the same concepts but totally different nomenclature than S3D

The Z speed isn't very important. I use 20mm/sec (1200mm/min) for all my printing moves with no underspeed as well, and getting great results. The faster you retract and whip the print head to the next location (travel speed & retract speed/distance), the cleaner your models will be.

My latest print is cleaner, increased temp to 250c. I still see some retract bumps and will increase the X/Y a little more to see if i can get it a little smoother. thanks for your invite it has help tremendously.

I meant "insight"

-

Ronnien55

- Posts: 60

- Joined: Mon Dec 08, 2014 2:50 am

- Location: Holly Springs NC

Post

by Ronnien55 » Wed Feb 18, 2015 1:57 am

Ronnien55 wrote:Ronnien55 wrote:insta wrote:You're right, you have to print slowly, but because it oozes so much you need fast travel (non-printing) moves. Sorry, I use slic3r primarily, which has the same concepts but totally different nomenclature than S3D

The Z speed isn't very important. I use 20mm/sec (1200mm/min) for all my printing moves with no underspeed as well, and getting great results. The faster you retract and whip the print head to the next location (travel speed & retract speed/distance), the cleaner your models will be.

My latest print is cleaner, increased temp to 250c. I still see some retract bumps and will increase the X/Y a little more to see if i can get it a little smoother. thanks for your invite it has help tremendously.

I meant "insight"

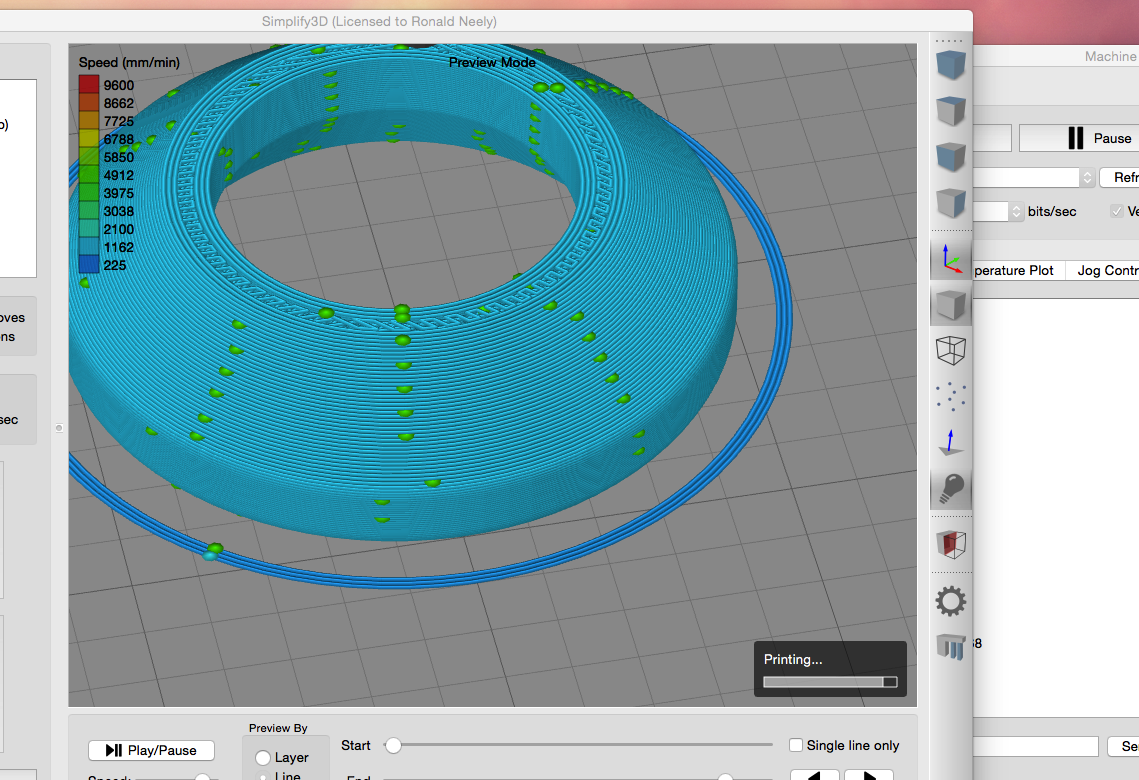

Made adjustments but I am still having some retraction issues. here is the print preview showing where they appear on the printed part.

- Snip20150217_1.png (656.97 KiB) Viewed 12706 times

the retractions appear exactly as it appears in the preview

-

jimc

- Posts: 2888

- Joined: Wed Apr 09, 2014 11:30 pm

- Location: mullica, nj

-

Contact:

Post

by jimc » Wed Feb 18, 2015 2:51 am

i have not had good luck with retracting ninjaflex at all. as insta said you can snap it back real quick at something high like 5-6mm but the stuff really just stretches like a rubber band so is only pulling it back just a little down in the nozzle. once it has retracted a little then i find it wont begin printing right away at the start of a line because it just compresses and wont start extruding right away when it returns from the retraction. it certainly doesn't work on every model but i try to avoid retractions whenever possible or dont spread them all over the model. set them to be all in one line like a seam then you can easily razor blade the bumps off when done or even take a soldering iron on low temp and smooth the bumps out.

-

Ronnien55

- Posts: 60

- Joined: Mon Dec 08, 2014 2:50 am

- Location: Holly Springs NC

Post

by Ronnien55 » Wed Feb 18, 2015 3:23 am

Thanks Jim, I have increased my X/Y to 18000.oo and it seams to have made it better, at least far less bumps. It is some tough stuff to run. Trying to make Skin brakes and it looks promising.

-

Ronnien55

- Posts: 60

- Joined: Mon Dec 08, 2014 2:50 am

- Location: Holly Springs NC

Post

by Ronnien55 » Thu Feb 19, 2015 1:20 am

jimc wrote:i have not had good luck with retracting ninjaflex at all. as insta said you can snap it back real quick at something high like 5-6mm but the stuff really just stretches like a rubber band so is only pulling it back just a little down in the nozzle. once it has retracted a little then i find it wont begin printing right away at the start of a line because it just compresses and wont start extruding right away when it returns from the retraction. it certainly doesn't work on every model but i try to avoid retractions whenever possible or dont spread them all over the model. set them to be all in one line like a seam then you can easily razor blade the bumps off when done or even take a soldering iron on low temp and smooth the bumps out.

Thanks Jim part looks much better when I put them in one line. A lot easier to clean up.

-

Mount PrintMore

- Posts: 34

- Joined: Mon Apr 14, 2014 4:09 am

Post

by Mount PrintMore » Sun Feb 07, 2016 4:44 pm

I've been dabbling with Ninjaflex this weekend on my M2 with the V4.

At first, I had some issues just getting the material started in the hotend, but I found that if I reduced the jog rate in S3D down to 60 mm/min it would push through the extruder all day. Even at 100 mm/min it would just wrap around the extruder drive gear. I think for ABS or PLA this number is more like 250 mm/min, so it's a huge difference.

I'm running the extruder at 235C and printing on glass with a little hairspray at 40C.

I have the fan come on to 100% for the second layer.

I slowed my speeds way down as everyone has suggested, and printed a little timing belt model right out of the gate that came out well. I had retraction completely turned off, and there are two small spots that built up with material during travel moves, but nothing major.

I did turn retraction back on and am currently using 3mm of retraction. This seemed to help.

I went on to running some more typical calibration parts that I use, and overall the parts come out okay. It seems like in general it is under extruded. I'm running a 0.35 mm nozzle and the "auto-width" is working toward an 0.42 mm extrusion width. I'm been pushing the extrusion multiplier upward and upward to try to fill this in, but I'm not seeing much difference.

I'm running a flexible octopus model right now, but I think once that's done I'm going to set my extrusion width to manual and turn it down to something closer to 0.35mm to better match the nozzle.

I did try running a small test part where I was printing over support material. The part printed okay, and most of the support material came off okay, but the surface that was supported is very rough. Any suggestions for improving that?

-

Mount PrintMore

- Posts: 34

- Joined: Mon Apr 14, 2014 4:09 am

Post

by Mount PrintMore » Mon Feb 08, 2016 12:05 am

So ran a few parts with an Extrusion Multiplier of 100 and with the extrusion width manually cranked down to 0.38 and 0.40.

In both cases, the nozzle was clearly dragging in and picking up some material and I got prints that were worse than what I was getting at 0.42.

I have to admit, this surprised me.

Anyone have an insights to share?