v4 Status

Re: v4 Status

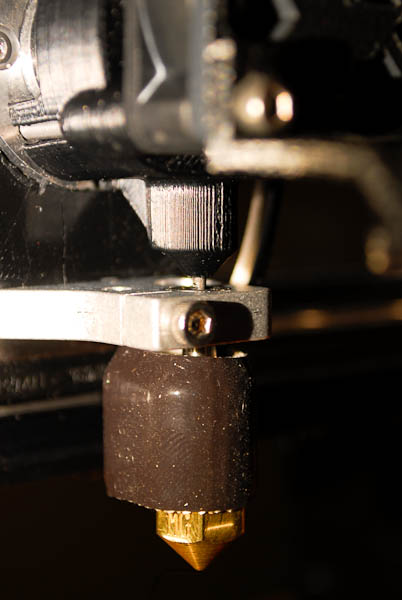

V4 up and running. Ran some ABS part turned out looking good.ready to resume printing.

Re: v4 Status

Here it is installed, very straight forward.

Re: v4 Status

That part looks awesome! So would you suggest to move from V3B to V4? Is print quality better? I'm thinking about it

Re: v4 Status

Ronnien55, it looks good and it might just be deceiving in the picture you posted but you don't want your actual hot end to touch the conical (cone shape) part of your extruder drive. There should be a bit of a separation between the two parts like shown below. If yours is touching just loosen the screw and drop it down a bit. (make sure its off though  )

)

-Steve

-Steve

____________________________________________________

See my projects at https://www.theneverendingprojectslist.com

See my projects at https://www.theneverendingprojectslist.com

Re: v4 Status

There is a small piece of PTFE in the v4. It can be accessed by removing the jam nut on the end of the v4 using a 3/32" hex key. You'll probably need to do this with the hot-end hot so do it carefully. If you need to clean the v4, you can remove the piece of PTFE by removing the jam nut. Use a wood screw or something to carefully grip the piece of ptfe and pull it out. Clean the hot-end (acetone, heat, or however). Cut a new piece of PTFE (0.330" length, McM part: 52335K32). Insert PTFE. Replace/tighten jam nut.

Rick

Rick

Re: v4 Status

rick, double chk that part #. that one says its an allen key

Re: v4 Status

corrected. thanks jim!

Re: v4 Status

Is the all-metal v4 variant DOA now?rpollack wrote:corrected. thanks jim!

Custom 3D printing for you or your business -- quote [at] pingring.org

Re: v4 Status

no, it is not DOA.

Re: v4 Status

Minimum order is 5 feet. So that's about 180 changings worth... I guess 90 if you have dual extruders.rpollack wrote:Cut a new piece of PTFE (0.330" length, McM part: 52335K32).