Tim wrote:some people get a bit obsessive about dialing in these numbers

That would be me, I suppose... [grin]

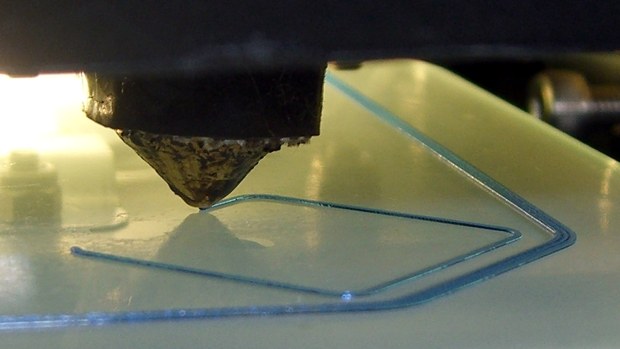

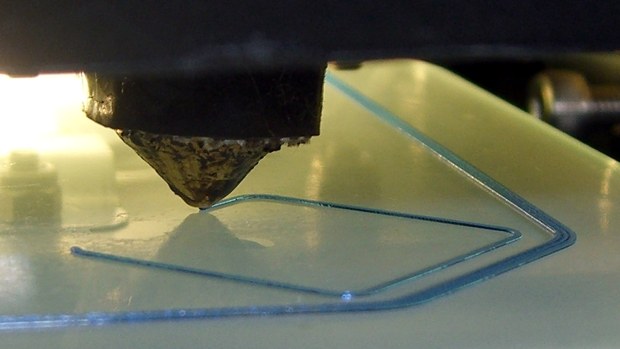

A good value for the filament diameter gets you almost all of the way to the goal. Contemporary filaments (seem to) have much more consistent diameters these days, so the measurement isn't nearly as fussy as it once was and, if

you're not fussy, the nominal diameter should be Close Enough.

The Extrusion Multiplier provides a first-order correction for

everything else, from material properties to the filament drive gear to the nozzle diameter tolerance. With that number set, the actual thread width should stay close enough to what the slicer expects over a reasonable range of all the other variations. Given good filament and the M2's mechanical stability, the slicer's default Extrusion Multipler should be Close Enough.

The nozzle-to-platform distance for the first layer seems to pose the most trouble, because folks can't measure (or believe!) the 0.2 mm difference between

no extrusion (because there's no gap!) and

no adhesion (because there's no contact!), with various maladies lying in wait within those limits. Worse, that applies over the entire expanse of the platform and requires far too much manual fiddling to get both the offset and alignment right. Automagic distance-and-alignment sensors should eliminate that hassle and, perhaps, nobody will ever (need to) measure anything again.

Unlike you folks, I chuck up one roll of filament, do my ritual dance, and then run with the same settings for months on end: create solid models, slice 'em, Fire the M2 Cannon, and It Just Works Every Time:

http://softsolder.com/2015/09/04/thinwa ... er-images/

Obligatory XKCD:

https://xkcd.com/1479/

I can feel my knowledge becoming obsolete: that's a Good Thing!