I'm trying to choose a 3D printer for small production runs of electronic enclosures, sorta bridging the gap before injection molding. I really like the looks of the M2 but trying to understand if it's going to be good enough.

Support material needed?

When do I need to start printing support material? What kind of overhang length and angle can be reliably high quality printed with a single extruder? My designs really only have rounded corners about 3mm radius or less on a 1.5mm thick wall. Would that print well without support? I've attached a couple STLs if that helps. Does anyone think I'd need the dual upgrade to print these well?

What does 10micron x-y precision mean?

I'm also having trouble grasping the precision specs. If x-y precision is .01mm, does that mean my circular button holes in the x-y plane will be circular to within .01mm with centers accurate to .01mm? Or does nozzle size affect that? 10 microns seems pretty amazing, I'd be happy if 50 microns was reliable.

Is it really this cheap?

And a final consideration for me is total part cost. It seems very low by my calculation, I'm worried I'm missing something. Can someone correct me? or add a hidden cost I'm not aware of?

PLA = $35/1kG

Density of PLA = 1.24g/cc

My model volume: 10cc

= $0.42 per model

That's cheaper than an injection mold run of 500 parts in a single cavity. Are there any other consumable parts I don't know about? Can I expect my M2 to run 24/7 for 6 months without major expenses?

Thanks so much for your help guys! Look forward to joining you if this proves as good as it sounds.

When is a dual extruder/supports required?

When is a dual extruder/supports required?

- Attachments

-

Enclosure - Top.stl

Enclosure - Top.stl- (601.55 KiB) Downloaded 480 times

-

Enclosure - Bottom.stl

Enclosure - Bottom.stl- (696.37 KiB) Downloaded 445 times

Re: When is a dual extruder/supports required?

Those round edges are the bane of my existence when customers ask me to print them. They're the worst-case scenario for single-support material -- sorry. Dual extrusion will help, but you'll have to use PVA, and each part will require cleanup. Is there any way you'd be willing to redesign the part (for the printing) to have a chamfer instead of a radius around the edge? If you make it 45 degrees, there's no support material needed at all.

You're right on the per-part price, assuming the printer is free and your time is worthless. There's no additional costs or consumables, except maybe a bed treatment like hairspray. I personally use hairspray on about 60% of my printers, and only print PLA/PETG/HIPS on them. I use dollar store hairspray, and 1 $1 can lasts about 40 prints, so the cost is pretty negligible. The M2 will actually fit 3 sets of tops/bottoms per run, and do a single run in about 2 hours. If you have swappable glass plates, you can begin printing the next set immediately, and do 500 parts in under a month. (of course if you happen to know a guy who runs a printing farm something something it can go even faster but cost more).

Basic maintenance on the printers is cleaning the filament path when it jams, lubrication when it gets noisy, and keeping the bed level.

--- edit ---

The rest of your questions:

3 sets of parts is 77 grams of PLA @ 70% fill (incidentally your parts are so thin that infill doens't really matter). Divide this into 1kg and you'll get the number of 'sets of 3' per spool. Materials really are cheap -- so use good ones. eSUN's PLA+ or Breathe3DP's PLA++ are my go-to recommendations at this point, they're blended PLAs that print pretty smooth. The MakerGear branded PLA is also nice (I think it's OEM'ed by Village Plastic?), I'm still trickling through a few spools I've gotten from printer purchases.

You're right on the per-part price, assuming the printer is free and your time is worthless. There's no additional costs or consumables, except maybe a bed treatment like hairspray. I personally use hairspray on about 60% of my printers, and only print PLA/PETG/HIPS on them. I use dollar store hairspray, and 1 $1 can lasts about 40 prints, so the cost is pretty negligible. The M2 will actually fit 3 sets of tops/bottoms per run, and do a single run in about 2 hours. If you have swappable glass plates, you can begin printing the next set immediately, and do 500 parts in under a month. (of course if you happen to know a guy who runs a printing farm something something it can go even faster but cost more).

Basic maintenance on the printers is cleaning the filament path when it jams, lubrication when it gets noisy, and keeping the bed level.

--- edit ---

The rest of your questions:

Resolution might be 0.01mm, but precision isn't. Don't rely on anything more than about 100 micron in X/Y without post-machining. Be happy if you get it, but don't count on it. The M2 is one of the better printers in this regard, any belt-driven machine is going to have these numbers.

What does 10micron x-y precision mean?

I'm also having trouble grasping the precision specs. If x-y precision is .01mm, does that mean my circular button holes in the x-y plane will be circular to within .01mm with centers accurate to .01mm? Or does nozzle size affect that? 10 microns seems pretty amazing, I'd be happy if 50 microns was reliable.

3 sets of parts is 77 grams of PLA @ 70% fill (incidentally your parts are so thin that infill doens't really matter). Divide this into 1kg and you'll get the number of 'sets of 3' per spool. Materials really are cheap -- so use good ones. eSUN's PLA+ or Breathe3DP's PLA++ are my go-to recommendations at this point, they're blended PLAs that print pretty smooth. The MakerGear branded PLA is also nice (I think it's OEM'ed by Village Plastic?), I'm still trickling through a few spools I've gotten from printer purchases.

Custom 3D printing for you or your business -- quote [at] pingring.org

Re: When is a dual extruder/supports required?

Thanks very much for the clarification! Good to know it's this cheap. And yes, if I can save $10,000 on molds, I'd certainly consider redesigning with chamfer.

So then essentially the x-y tolerance is 100micron? So if I make a round button of diameter 10mm and a hole of diameter 10.2mm, that's expected to fit?

Can I pay someone to print a few sample parts with a properly setup M2 so I know what the potential is?

So then essentially the x-y tolerance is 100micron? So if I make a round button of diameter 10mm and a hole of diameter 10.2mm, that's expected to fit?

Can I pay someone to print a few sample parts with a properly setup M2 so I know what the potential is?

Re: When is a dual extruder/supports required?

0.2mm is actually what I tell my customers to leave for clearance if they want a smooth fit, so you've got it exactly right. Most people don't get it, so I run my machines -0.11mm for good fit, but if you order from me I'll do exactly the sizes you send.

And, yes, please hire me: https://www.3dhubs.com/kansas-city/hubs/bryan

And, yes, please hire me: https://www.3dhubs.com/kansas-city/hubs/bryan

Custom 3D printing for you or your business -- quote [at] pingring.org

Re: When is a dual extruder/supports required?

In a perfect world, yes, that would be true... [grin]noland wrote:a round button of diameter 10mm and a hole of diameter 10.2mm, that's expected to fit?

Among other things, the orientation of a feature affects its tolerances: a hole printed horizontally won't fit a peg printed vertically, because they have different shapes. Resolution along the Z axis depends on the layer thickness, so you're looking at 0.10 to 0.30 mm slices, quantized in fairly large chunks. For example, a 3 mm horizontal hole printed with 0.20 mm layers will span only 15 layers, have a somewhat oval shape due to overhang, and look rather gritty compared to the same hole printed vertically.

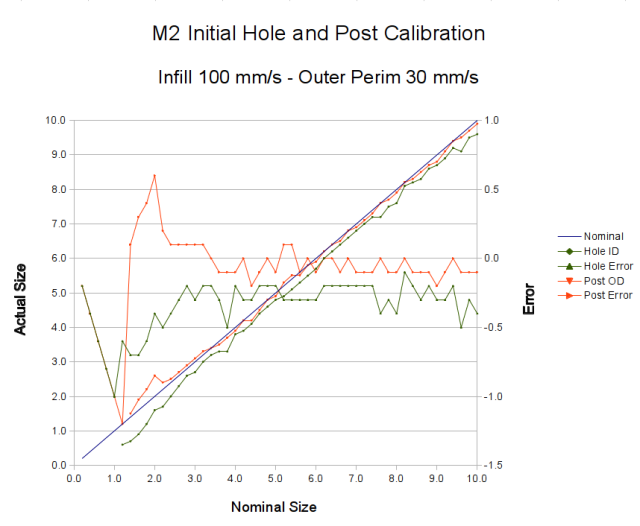

Some time ago, I ran off a peg-and-hole test piece that produced informative results:

https://softsolder.com/2013/04/21/maker ... t-objects/

Above about 3 mm diameter, a 0.20 mm Finagle Constant works pretty well, but only because that's the difference between holes and posts. When you want better absolute accuracy for both positive and negative features (perhaps to accept metal pins or fit into machined recesses), you need two different constants; something like +0.30 and +0.10 mm might suffice.

Below about 3 mm diameter, 3D printing will be the wrong process for the job...

Re: When is a dual extruder/supports required?

Wow, thanks for the detailed data. I find it counter intuitive that the errors for both peg and hole are on the minus side. I would think if the printer is encroaching on the hole then it would also put too much material into the peg.

My pegs and holes though at around the 8 - 10mm area so I think the 200um tolerance will just be good enough. I'm going to order some prints from insta and see how they look.

My pegs and holes though at around the 8 - 10mm area so I think the 200um tolerance will just be good enough. I'm going to order some prints from insta and see how they look.

Re: When is a dual extruder/supports required?

It's a physics thing: the nozzle tends to drag the gooey plastic thread behind it, so the net force on the perimeter thread of a circle always points inward to make it a bit smaller than you'd expect. Posts have less error than holes, because (if you do the inner threads first) the perimeter threads butt up against the infill.noland wrote:counter intuitive that the errors for both peg and hole are on the minus side

Nophead knows more than any one person really should about the subject:

https://hydraraptor.blogspot.co.uk/2011 ... holes.html

https://hydraraptor.blogspot.com/2014/0 ... wrong.html

I use a version of his polyholes function to produce horrible-but-accurate holes, then ream with a drill of the appropriate size when I need a better fit.

One careful measurement outweighs a thousand expert opinions ...order some prints from insta