Page 1 of 2

Metal Casting

Posted: Wed Aug 05, 2015 6:46 pm

by Mark the Greater

Hello Again!

Anyone here turn their prints into metal parts? That is my end-goal here. As of now there is a lot of bits and pieces out there, not a lot of useful information though. I would love to find some like-minded people and share ideas!

Re: Metal Casting

Posted: Wed Aug 05, 2015 8:14 pm

by ednisley

Mark the Greater wrote:Anyone here turn their prints into metal parts?

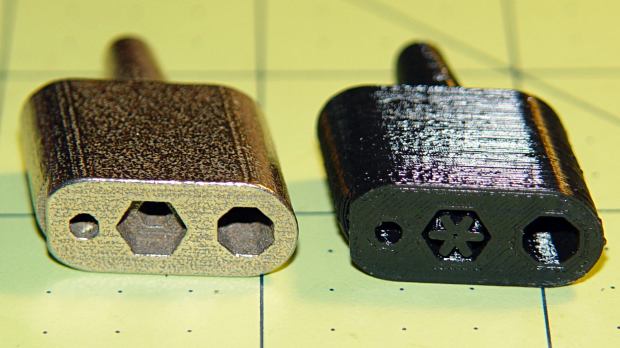

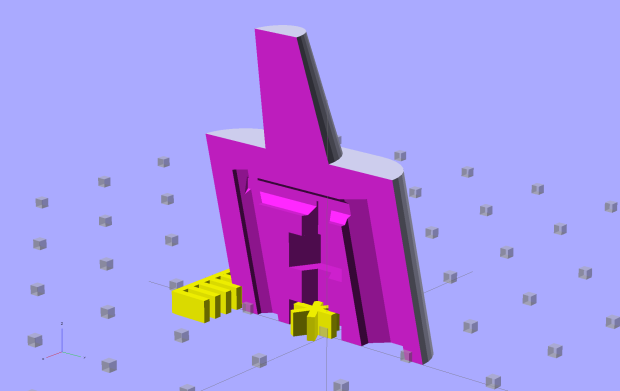

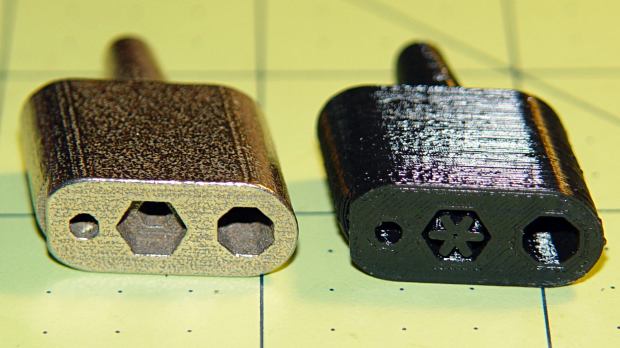

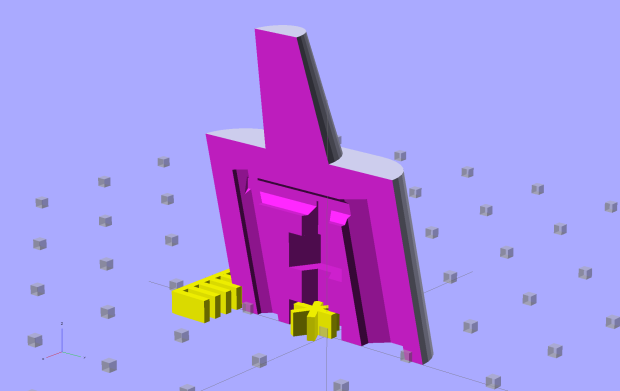

I iterated with plastic parts until they fit and functioned correctly, then had Shapeways produce the same shape in their "stainless steel" process:

http://softsolder.com/2014/01/06/browni ... l-version/

It's actually bronze-infused stainless steel powder, which was Good Enough for my purposes.

A bunch of internal features ruled out subtractive machining:

Not the cheapest way to get it done, but

much easier than investment-casting stainless steel in a backyard furnace... [grin]

Re: Metal Casting

Posted: Wed Aug 05, 2015 8:20 pm

by Bratag

Mark the Greater wrote:Hello Again!

Anyone here turn their prints into metal parts? That is my end-goal here. As of now there is a lot of bits and pieces out there, not a lot of useful information though. I would love to find some like-minded people and share ideas!

Haven't done anything yet but have been toying with the idea of both cold metal casting , which is a resin combined with a 1:1 ratio of iron etc and the poured into a silicone mold. Good mainly for decorative stuff

Then there is lost filament casting, which used to consist of printing in pla then surrounding with a mold and essentially burning the pla out with the hot metal. While it worked ok it had the risk of left over PLA or PLA residue. Now there is this MOLDLAY which is a filament that can be printed at lower temps have a mold poured around it and then be baked in an oven at high temps leaving you with a perfect mold to pour into. Naturally this requires you to have a forge and a place to use it. The King Of Random has a nice video series on a little forge that is easy to make/use.

Re: Metal Casting

Posted: Wed Aug 05, 2015 8:28 pm

by Mark the Greater

That's is pretty cool Ed. I am leaning towards aluminum, brass, copper so backyard forging is within my scope. I think.

Bratag, that is awesome. I know Formlabs has a casting resin that looks pretty neat. I should have assumed that FFF would have someone working on an equivalent.

Re: Metal Casting

Posted: Wed Aug 05, 2015 11:26 pm

by insta

Re: Metal Casting

Posted: Thu Aug 06, 2015 1:01 am

by jimc

hereis something i did or i should say had done. when i restored this safe the brass hinge finials were missing so i modeled and had them casted in brass.

https://www.simplify3d.com/restoring-excellence/

Re: Metal Casting

Posted: Fri Aug 07, 2015 8:45 pm

by Alloy

Being a foundry man, I know a little about pouring metal. The lost PLA process works in an investment casting (lost wax) way not an evaporative pattern (lost foam) way. Make your part, build a ceramic shell around it, burn out the pattern, pour metal in the cavity, and even this has some problems with PLA residue getting left behind and causing defects. I have never done this but I have been around when others are doing it. As for trying to burn the PLA out with the metal, the people I know have not had too much success with ductile iron let alone even trying it with aluminum.

Re: Metal Casting

Posted: Fri Aug 07, 2015 9:10 pm

by Mark the Greater

Alloy wrote:Being a foundry man, I know a little about pouring metal. The lost PLA process works in an investment casting (lost wax) way not an evaporative pattern (lost foam) way. Make your part, build a ceramic shell around it, burn out the pattern, pour metal in the cavity, and even this has some problems with PLA residue getting left behind and causing defects. I have never done this but I have been around when others are doing it. As for trying to burn the PLA out with the metal, the people I know have not had too much success with ductile iron let alone even trying it with aluminum.

Very interesting. Here is a question: Rather than burn out the PLA, or ABS, or whatever, what if you just melted it out? I have no idea how well this stuff flows. I doubt it would be ideal but would it be better than just burning it out? Or, are these the same thing and I am just confused?

Re: Metal Casting

Posted: Fri Aug 07, 2015 9:35 pm

by Alloy

Mark the Greater wrote:

Very interesting. Here is a question: Rather than burn out the PLA, or ABS, or whatever, what if you just melted it out? I have no idea how well this stuff flows. I doubt it would be ideal but would it be better than just burning it out? Or, are these the same thing and I am just confused?

You need high temperatures to get through the insulating shell, that the PLA comes out in bursts of flame. The way I have seen it done is with a burner ring and high pressure natural gas. The kiln probably works better...

Re: Metal Casting

Posted: Fri Aug 07, 2015 10:02 pm

by Tim

Alloy wrote:You need high temperatures to get through the insulating shell, that the PLA comes out in bursts of flame. The way I have seen it done is with a burner ring and high pressure natural gas. The kiln probably works better...

I would assume that's the whole reason for developing that new "moldlay" filament, waxy stuff that just melts away. . .