Yeah, ok.

For my first venture into the CNC world I wanted something that was not too expensive but had the potential to do real work. I don't have a lot of information on the Shapeoko3, so whatever I say here comes from reading on the net which we all know never contains any mis-information.

The X-carve is mostly an open source machine much like the M2. Shapeoko3 is rumored to be more proprietary.

Although I have not personally dealt with M2 support, from the reading that I've done on this forum Makergear support is superb. My experience with X-carve support is better than the reports of M2 support. Shapeoko3 doesn't have much support yet, but may come with time. Shipments on the Shapeoko3 were spotty and delayed (X-carve has a back log like Makergear - it takes about 4 weeks from order to delivery).

I was primarily interested in getting a 3 dimensional workspace that was computer controlled. One of the weak points of the X-carve is the basic spindle that they sell. It is very problematic and many forum members went straight to a DeWalt router instead of the Inventables spindle. Which is one of the good points of this company. As many people realized the limits of the stock spindle and expressed their desire to move to the DeWalt router, Inventables came out with a spindle mount that would fit the router within a matter of months.

So, for me the Shapeoko3 was not even in the running. Mostly due to support issues and the report on the net that the Shapeoko3 team was very small and the leader acknowledged that they were very understaffed.

I didn't look at the Shapeoko3 forum (if they have one) but I've spent a lot of time on the X-carve forum. People there are just as willing to help as the people on this forum, but they are not as knowledgeable as folks here. We're all learning together.

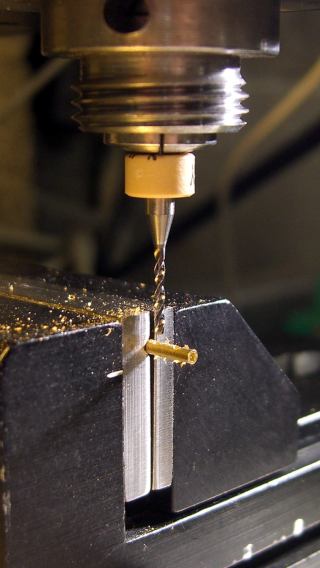

Most people on the forum seem to be carving wood projects, but there is a group of people that are milling 6061 Aluminum with some success. Some are using it for engraving, some for signage, some for carving foam and acrylics.

I haven't had mine long. Since I don't have a good location set up for milling yet, I have 3D printed an ink pen mount for the spindle mount so that I can test and tune my machine in the house.

It is an entry level machine and I think is a great point to start from to learn about this type of machine, but if you have heavy production ideas you might want to look at one of the more expensive machines. This allows me to test the waters and see what can be done and gives me a learning platform that has good potential without breaking the bank.

Hope this helps. If you have specific questions - send them. I'll do my best to get the answer.

Larry