Page 2 of 3

Re: Using ABS

Posted: Sun Apr 27, 2014 1:59 pm

by Toby

Capt. John wrote:I'll have to review the replies, but don't see admin from Makergear stepping in to help.

This is not what the Amazon reviews said. Instead, help is provided by fellow members with the

best intentions to help others. For this I thank all who offered their help to me.

In the S3D program FFF settings under scripts there's a bugaboo.

M108 S255 ; turn on M2 fans (this was M108 S155 until I changed it) for the number 3b hot end.

G28 ; home all axes

G1 Y50 Z0.3 F9600 ; move forward to avoid binder clips

G1 X205 Z10 ; move off platform

G1 Z0.4 ; position nozzle

G92 E0 ; zero extruder

G1 E25 F250 ; purge nozzle <------- this was set low at F225, moved it to F250, shouldn't it be C250?

G92 E0 ; zero extruder

G1 X190 Z0.1 E1.0 F1200 ; slow wipe

G1 X180 Z0.25 ; lift

Thanks for your help beforehand

I haven't been following this thread too closely since I haven't printed in ABS. If you want help from Makergear, the way to go is through their support email. This is the user group so the help you'll get here will be from other users. Rick only occasionally steps in if someone is obviously having a hardware issue, and then he just says "Contact Makergear support."

In terms of the startup script, that F225 in the G1 command isn't about temperature, it's feed rate. (Under the circumstances that was a reasonable guess on your part though.) There are various places to find descriptions of the G-code commands. If you search under "Marlin G-code" or the like I think you'll find it. If not let me know and I'll see if I can dig something up.

Re: Using ABS

Posted: Sun Apr 27, 2014 2:17 pm

by jimc

capt, those set screws tend to work themselves loose. a little locktite on it will keep that from happening. as toby said this is not makergear support exactly. not every thread is monitored by makergear. if you have an issue that cant quickly be resolved here then you need to email makergear support HOWEVER i dont really think this is a hardware issue. it sounds more like an s3d issue or just a setting problem. either way i dont think its a big one and most of us here can help you straighten it out. so with your first layer temp now set to 250 are you still seeing a temp drop? if so can you post you fff file for this or your .factory. you will need to zip the files before upload.

Re: Using ABS

Posted: Sun Apr 27, 2014 3:27 pm

by Capt. John

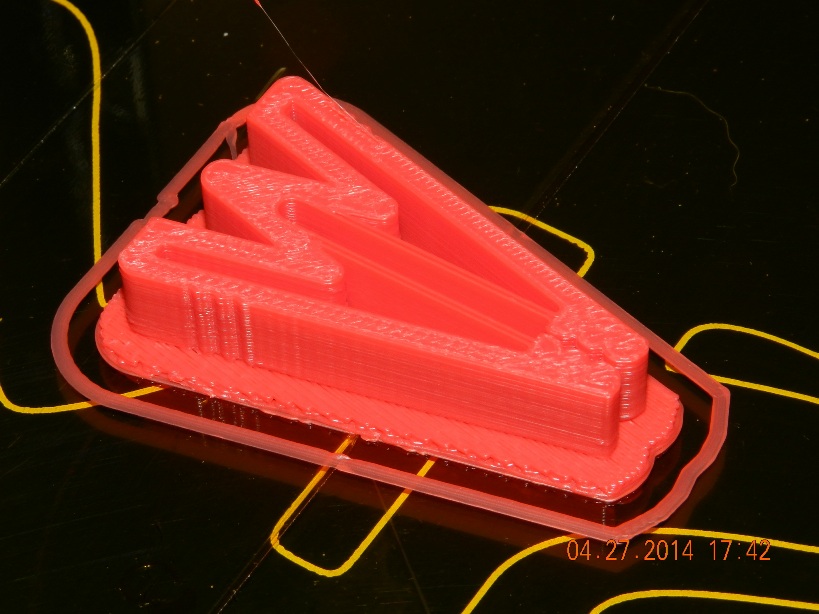

Curly Qs in the skirt, laid out before the raft?

This does not look like that when I print in PLA.

Raised the setting to 260 to get the ABS to stick to the bed Kapton tape:

- ABS.jpg (236.41 KiB) Viewed 14039 times

Re: Using ABS

Posted: Sun Apr 27, 2014 4:14 pm

by jsc

Check your z-height, it looks high to me.

Try clicking the z-stop end knob clockwise one or two clicks while the skirt is going down to see if that helps get rid of the little loops. If that works, adjust your bed height closer to the nozzle.

Re: Using ABS

Posted: Sun Apr 27, 2014 8:13 pm

by MichaelH

An easy test is set your temperature to 250C and the Bed to 96C manually and print the Bracelet from MakerGear.

This is what I did when having trouble with filament.

This way you know the GCode works and you need to set the Temp. anyway.

Re: Using ABS

Posted: Sun Apr 27, 2014 10:34 pm

by jimc

i dont use rafts but just looking at the skirt it looks like your printing really far away from the bed. even if it comes out of the nozzle all curly you wont really see it much when printed because its being squished into place. if its too far off the bed then the extruded plastic just goes where it wants to.

Re: Using ABS

Posted: Mon Apr 28, 2014 2:35 am

by Capt. John

Success 15 hours later! Blind alley was the set screw, I will be ordering a spare gear and extra set screw.

I use 24 pound paper, my business card a thick, using common item to measure is OK for some,

but I have calipers that read to .0000 and would have rather mic-ed the dimensions.

Raised the bed with the hard to get to magic set bolt with the jam nut a bit.

ABS bag clip printed like a charm:

- ABS_done 001.jpg (148.14 KiB) Viewed 14030 times

Many thinks for the help and sharing your knowledge with newbies who are struggling.

Re: Using ABS

Posted: Mon Apr 28, 2014 2:38 am

by jimc

pick yourself up a set of feeler gauges for setting bed gap. paper just varies alot. you want to be able to take an accurate measurement. .006-.005" gap is about right.

Re: Using ABS

Posted: Mon Apr 28, 2014 6:20 am

by Capt. John

Members here are wonderful!

What a resource this board is!

Pretty stoked after conquering ABS, already had a handle on PLA that seems to be more forgiving.

First time with the Aquanet, that stuck down the ABS like a magnet on top of the Kapton.

Will try just the hair spray soon.

Re: Using ABS

Posted: Mon Apr 28, 2014 7:13 am

by jsc

Placing the jam nut on the bottom of the platform rather than the top makes it somewhat easier to get to There is also a 7mm printable wrench on thingiverse that makes height adjustments very much easier, and you won't get grease on your hand. Links are in my "M2 Tips" thread in the Tips subforum.