Fine Detail Printing

Fine Detail Printing

Hi All, I'm trying to print some small enclosures with very fine details (250~300um) using my MakerGear M2, and am looking for suggestions for hardware setup and slicer parameters.

I'm currently printing with a 0.35mm extruder, but am looking at purchasing a smaller (0.25mm) one soon, as well as upgrading to the E3D v6 or MG v4 hot end. I've also added a fan duct for the main 50mm fan and added a second 50mm at 90 degrees to help with cooling

Can anyone recommend any further hardware modifications to help with these small prints?

What should I be looking at in terms of print speed, layer height, extrusion width, print temp, etc to resolve these fine details?

Are there any filaments that are better for printing small features than the standard PLA I'm using?

I'm currently printing with a 0.35mm extruder, but am looking at purchasing a smaller (0.25mm) one soon, as well as upgrading to the E3D v6 or MG v4 hot end. I've also added a fan duct for the main 50mm fan and added a second 50mm at 90 degrees to help with cooling

Can anyone recommend any further hardware modifications to help with these small prints?

What should I be looking at in terms of print speed, layer height, extrusion width, print temp, etc to resolve these fine details?

Are there any filaments that are better for printing small features than the standard PLA I'm using?

Last edited by spizzak on Wed Aug 12, 2015 3:35 pm, edited 1 time in total.

Re: Fine Detail Printing

Switching to a smaller extruder will be the only thing that has a first order effect on ability to print small details. Here's an example: viewtopic.php?f=6&t=2267

Detail resolution is limited mainly by the width of the filament being extruded. You can get higher resolution in the z axis by printing with a low layer thickness, so if your model is amenable to it, you can try orienting it so your fine details are on a vertical surface.

Detail resolution is limited mainly by the width of the filament being extruded. You can get higher resolution in the z axis by printing with a low layer thickness, so if your model is amenable to it, you can try orienting it so your fine details are on a vertical surface.

Re: Fine Detail Printing

Unfortunately, that's about a factor of ten below the capabilities of consumer-grade 3D printers.spizzak wrote:small enclosures with very fine details (25~30um)

The fundamental limit comes from the width of the extruded plastic thread, which will be no smaller than 0.3 mm: you cannot make a feature smaller than the thread width. In fact, it's difficult to make a feature smaller than two thread widths, because features must (*) have two walls, each about 0.3 mm wide.

You can make indentations less than a thread width, but, because you're producing an object using viscous molten goo, the edges won't be very crisp.

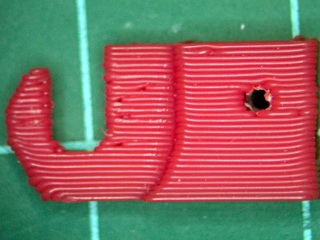

A close look at a caliper repair part shows the relation between the thread width and the object's outline:

http://softsolder.com/2011/05/27/thing- ... erfection/

The squares in the background are 0.5 inch. After all these years, it's one of the smallest things I've made.

(*) There are exceptions, but your success depends on your model, the slicing software, and the phase of the moon...

- Matt_Sharkey

- Posts: 347

- Joined: Mon Oct 20, 2014 3:10 pm

Re: Fine Detail Printing

Ed, your demonstration really relates to the analogy that i give people on 3D printing

"Imagine you want to make something 3D, but you're limited to using Pull 'N' Peel Twizzlers. "

In fact I think I'm going to make a lesson to introduce the kiddies to 3D printing that uses Twizzlers. I suspect I'll have 100% participation that day.

"Imagine you want to make something 3D, but you're limited to using Pull 'N' Peel Twizzlers. "

In fact I think I'm going to make a lesson to introduce the kiddies to 3D printing that uses Twizzlers. I suspect I'll have 100% participation that day.

- Mark the Greater

- Posts: 124

- Joined: Mon Jul 27, 2015 8:27 pm

- Location: Brookfield, IL

Re: Fine Detail Printing

Ha! I am going to steal this quote. Mine always involved a hot-glue gun analogy...Matt_Sharkey wrote:"Imagine you want to make something 3D, but you're limited to using Pull 'N' Peel Twizzlers. "

Love Always,

MtG

MtG

Re: Fine Detail Printing

I've not printed the whole of a model under .1mm but i've sucsessfuly printed external layers under .1mm using abs.

what i used was Skeinforge "Skin" setting - virtical and horizontal divisions.

i only used it down to 50um with a 40mm nozzle and that came out great...

you really need a rock solid bed, and you may need to slow down the print if your getting any vibrations.

i never had the desire to print the whole model at that resolution due to fears of layer adheasion issues and the shear time it would take to print.

its been some time since i've played with skeinforge, but its worth looking into. i am not sure of any of the more recent slicers can do this or not.

if your really interested in doing this, i can try and dig out the skeinfordge settings i used, as i still have it on my old laptop i i believe.

what i used was Skeinforge "Skin" setting - virtical and horizontal divisions.

i only used it down to 50um with a 40mm nozzle and that came out great...

you really need a rock solid bed, and you may need to slow down the print if your getting any vibrations.

i never had the desire to print the whole model at that resolution due to fears of layer adheasion issues and the shear time it would take to print.

its been some time since i've played with skeinforge, but its worth looking into. i am not sure of any of the more recent slicers can do this or not.

if your really interested in doing this, i can try and dig out the skeinfordge settings i used, as i still have it on my old laptop i i believe.

M2 - MKS SBase w Smoothieware, GLCD, 24v, Upg Z & extruder stepper - IR bed leveling, Astrosyn dampers X/Y/Z, MIC 6, Zebra, PEI, & glass Build Plates - E3D, V3B Hotends, & more - many other 3d printers - production printing.

Re: Fine Detail Printing

I printed a set of 10 tuba mouthpieces for somebody, with a 0.2mm nozzle and 0.1mm layers, at 50% density. It was on a fast core-xy machine running 100mm/sec print speeds and 4000mm/sec accel.

It took 41 hours.

It took 41 hours.

Custom 3D printing for you or your business -- quote [at] pingring.org

- Matt_Sharkey

- Posts: 347

- Joined: Mon Oct 20, 2014 3:10 pm

Re: Fine Detail Printing

thats where the dual extruder is necessary even if your infill is coming from a .35mm nozzleinsta wrote:I printed a set of 10 tuba mouthpieces for somebody, with a 0.2mm nozzle and 0.1mm layers, at 50% density. It was on a fast core-xy machine running 100mm/sec print speeds and 4000mm/sec accel.

It took 41 hours.

Re: Fine Detail Printing

It may have helped, mouthpieces are primarily cylindrical, doesn't leave a lot of room for infillMatt_Sharkey wrote:thats where the dual extruder is necessary even if your infill is coming from a .35mm nozzleinsta wrote:I printed a set of 10 tuba mouthpieces for somebody, with a 0.2mm nozzle and 0.1mm layers, at 50% density. It was on a fast core-xy machine running 100mm/sec print speeds and 4000mm/sec accel.

It took 41 hours.

Custom 3D printing for you or your business -- quote [at] pingring.org

Re: Fine Detail Printing

Slic3r tucks that away as the "Combine infill every n layers" setting: it prints n perimeter layers for every 1 infill layer, so you can use crazy-small perimeter layers without being interrupted by the heat death of the universe.innkeeper wrote:any of the more recent slicers can do this

There's an interlock with the perimeter layer thickness that prevents it from trying to print 1 mm thick infill layers, though.

Doesn't help in the XY plane, though, which is still limited by the nozzle diameter.