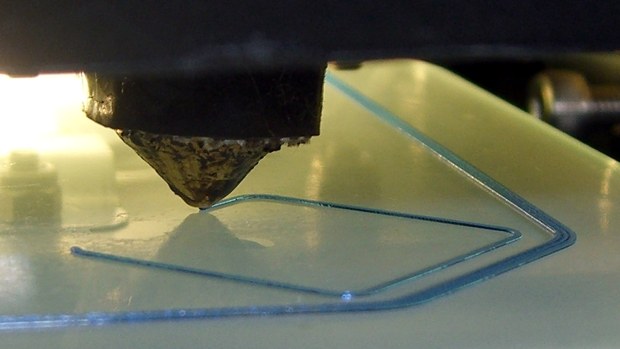

That's a 0.40 mm wide x 0.25 mm thick thread of PETG on glass, with hairspray gluing it in place.

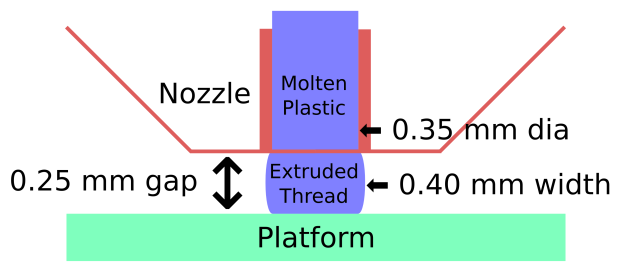

Here are the dimensions involved, more-or-less to scale:

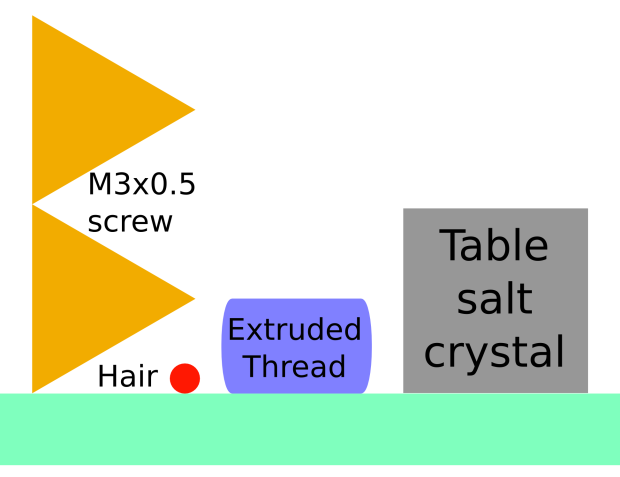

Here are some common household objects, more-or-less to the same scale:

The difference between a successful first layer and junk is about twice the diameter of the hair on your head. Raising the nozzle by 0.25 mm (four hairs) means the plastic coming out of the nozzle won't even touch the platform. Lowering the nozzle by 0.25 mm means no plastic comes out of the nozzle, because it's jammed against the platform.

If you don't have the platform aligned so that the gap remains within ±0.10 mm of the nominal 0.25 mm, then the thread won't adhere properly where the gap gets large and will overfill the layer where the gap gets small.

The platform rests on three M3x0.5 mm screws. One turn of the screw moves the platform at the screw vertically by 0.50 mm. That's twice the 0.25 mm thread thickness and will move the nozzle from "jammed against the glass" to "dangling in mid air".

The edges of the platform move about twice that distance, because the platform pivots around the screws you're not turning. Call it 1 mm vertically, four times the thread thickness, at the edge.

If you turn the alignment screw by 1/6 turn, just one wrench flat, that moves the edge of the platform about 0.20 mm vertically. That's the entire difference between "too low" and "too high".

If you're trying to align the platform by eye, you're doing it wrong. You must measure the actual as-printed results and adjust based on those measurements.

Start with the Beginner's Guide so you understand what's going on:

viewtopic.php?f=8&t=2778

Use this guide to get the platform aligned close enough to work:

viewtopic.php?f=3&t=2783

Calibrate your Extrusion Multiplier to make the printed thread width match the slicer's expectations:

viewtopic.php?f=3&t=1964

Then get perfect alignment by using thinwall boxes as height gauges:

http://softsolder.com/2015/09/04/thinwa ... er-images/

When all the boxes have the proper wall thickness and height, you can print more complex objects with ease. Until then, you're probably wasting time and plastic.

Once you've set the platform correctly, you won't have to touch it again for a long time, unless you're in the habit of pulling the platform off to remove objects or bashing it with a chisel to knock objects loose. Treat the platform with respect and it'll reward you with perfect results every time...