I've been having issues with my prints not coming out the way they did when I first got the M2, so I'm looking for any ideas suggestions as to what to do or what may be the cause of these issues.

When I try to print PLA with the hot end at <195C the extruder stepper stutters, I think its just too much pressure in the hot end and its causing material/ stepper to slip a little.

Even though I have leveled the HBP with glass and kapton tape on it to ~.001 in (.025mm) all four corners, my prints blob up in the back left and right corners where the layers start and end, when I try to print 25mmcu test pieces, I'm thinking I either don't have enough retract on the extruder or the z axis.

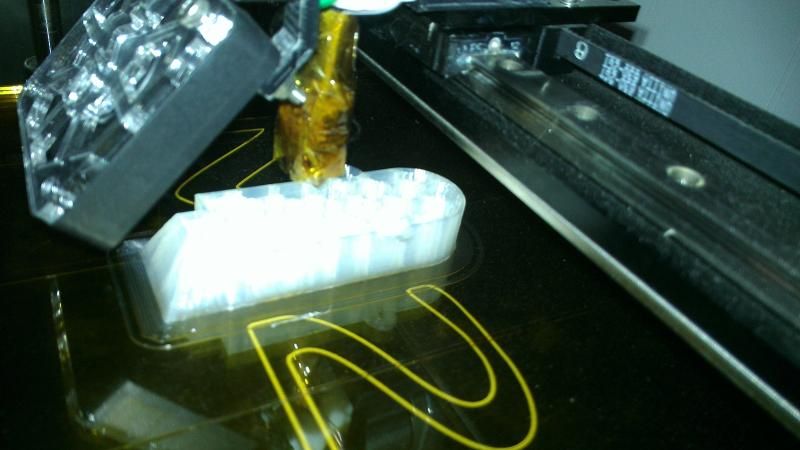

Last night while printing a 25mmX25X10 tile I noticed what looked like PLA oozing out from the fiber glass tape near the hot end ( My M2 is from 2013 about this time so I think its got a 12v V3 head with .35 hole), it would ooze out and retract every no and then but only for the first 5 layers then it was no more.

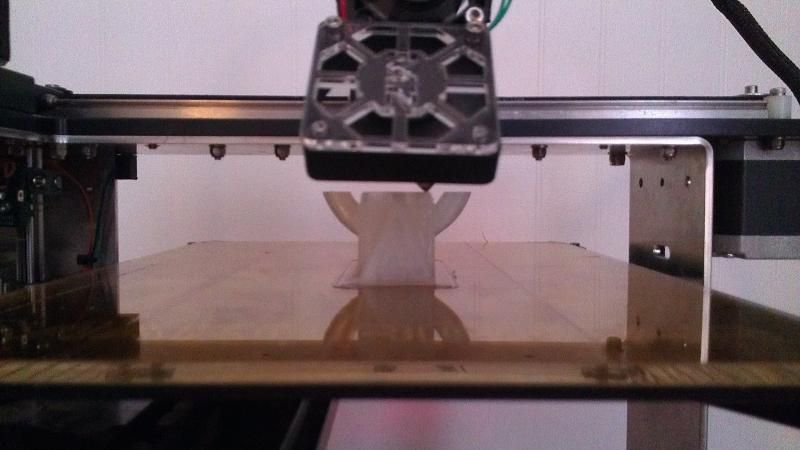

When it tries to print the top layers they are not flat with 40 or even 60% infill the layers sort of dip down into the empty space of the infill, I'm thinking this may be due extruder too hot or too close to layer, it even worse when I try to print taller items, it sounds like my hot end drags on the print.

Finally I'm noticing that the sides of my prints are adequately straight.

Thank you for any input.

Defective prints and maybe worn out hot end

Re: Defective prints and maybe worn out hot end

Your hotend may be clogging, especially if you're still on the original from 2013.

Get some Taulman 618 Nylon, or eSUN cleaner filament, and do a couple cold pulls on the hotend. You'll likely have to detach the hotend holder from the motor since cold pulls are removed at a temperature colder than the firmware will spin the motor.

Remove the rubber covers, and wire-brush the hotend clean, getting rid of all of the PLA debris left behind. The PLA is oozing out and over because it's struggling to extrude against a clogged and dirty nozzle.

Get some Taulman 618 Nylon, or eSUN cleaner filament, and do a couple cold pulls on the hotend. You'll likely have to detach the hotend holder from the motor since cold pulls are removed at a temperature colder than the firmware will spin the motor.

Remove the rubber covers, and wire-brush the hotend clean, getting rid of all of the PLA debris left behind. The PLA is oozing out and over because it's struggling to extrude against a clogged and dirty nozzle.

Custom 3D printing for you or your business -- quote [at] pingring.org

Re: Defective prints and maybe worn out hot end

If you do have a clogged hot end, and it sounds like you do, you may find some of the links in this thread of use: viewtopic.php?f=7&t=732&start=10

Especially in the second to last response (by me).

The (dis)assembly instructions were very helpful. The wrenches are a must, especially the 11mm one to get the nozzle off. The right sized drill bets help make sure you're getting everything out. And the paint stripper, that will get everything super super clean. Don't be daunted, it was my first time, too.

Especially in the second to last response (by me).

The (dis)assembly instructions were very helpful. The wrenches are a must, especially the 11mm one to get the nozzle off. The right sized drill bets help make sure you're getting everything out. And the paint stripper, that will get everything super super clean. Don't be daunted, it was my first time, too.

Re: Defective prints and maybe worn out hot end

Thanks for the info, I tried a few cold pulls since I made this post and you guys responded, and the cold pulls didn't seem to fix anything, took it to work today and used some of the drill bits there (we have down to 1/64 (.5mm)), finger drilled the extruder and now it seems to extrude vertical now, just started a 25mm^3 .05layer test part, will let you know how well it worked out, also because I could only use the .5mm bit I now get .42avg dia extrusion.

Re: Defective prints and maybe worn out hot end

Hotends are actually wear items, albeit slow ones. Yours might just be due for replacement.04kmorri wrote:Thanks for the info, I tried a few cold pulls since I made this post and you guys responded, and the cold pulls didn't seem to fix anything, took it to work today and used some of the drill bits there (we have down to 1/64 (.5mm)), finger drilled the extruder and now it seems to extrude vertical now, just started a 25mm^3 .05layer test part, will let you know how well it worked out, also because I could only use the .5mm bit I now get .42avg dia extrusion.

Custom 3D printing for you or your business -- quote [at] pingring.org