It seems that changes introduced in Slic3r since last year now prevent it from slicing the OpenSCAD model that produced the chain mail sheets described in my show-n-tell post:

viewtopic.php?f=6&t=1710

For whatever reason, Slic3r now mostly uses the infill pattern on the bottom layer of the bridges, so the threads don't run directly across the gap. Unfortunately, the failure isn't consistent, with a few bridges having the proper bridge pattern and most other with infill, which means I can't just reorient the links to make the bridges come out right.

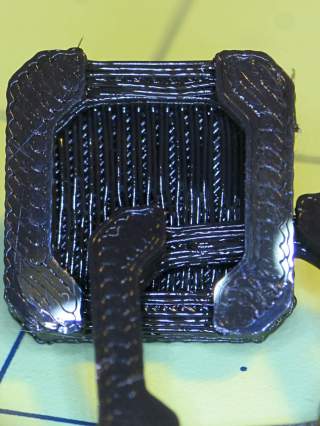

This picture is larger than I'd like, but it certainly shows the problem:

Three of the four bridges use infill and only one has proper bridging.

The first layer of these armor caps didn't work, either:

So I ran the STL files through Cura and KISSlicer, only to find neither created good bridges. I admit to not using those slicers, so perhaps it's a configuration issue, but they have fewer knobs than Slic3r and I didn't see anything obviously wrong.

As far as Slic3r is concerned, the STL files are manifold and have no problems. Meshlab shows a few self-intersecting faces on the peaks of the armor buttons, but a discussion on the OpenSCAD forum says that's an artifact of how Meshlab assigns vertices (or something like that).

After all that, I'd appreciate it if you folks would run the STL files through your slicer of choice and let me know what comes out.

The Slic3r bug report (Issue 2646) has a more detailed description & pix of the problems:

https://github.com/alexrj/Slic3r/issues/2646

The attached ZIP file has the OpenSCAD source and the failing STL files.

Thanks kindly...

Chain Mail Slicing Challenge

Chain Mail Slicing Challenge

- Attachments

-

- Slicer 0d822f0 - bridging.zip

- A ZIP file containing the OpenSCAD source, Slic3r configuration, some pix, and two STL files that produces small sheets of chain mail.

- (1.66 MiB) Downloaded 299 times

Re: Chain Mail Slicing Challenge

Ed, this is in Slic3r 1.2.1:

The links: Cap bridging: Looks okay to me. Here's how S3D handles the cap bridging, it opts to bridge just the interior gap rather than the whole thing:

The links: Cap bridging: Looks okay to me. Here's how S3D handles the cap bridging, it opts to bridge just the interior gap rather than the whole thing:

Re: Chain Mail Slicing Challenge

Since Jin beat me to it, I can only concur that Simplify3D does the right thing for all the bridging.

Re: Chain Mail Slicing Challenge

s3d must have fixed theirs. didnt we go through this with jin's wallet thing where s3d was doing some weird bridging? it only bridged the edge or something. sort of like in ed's slic3r pictures.

Re: Chain Mail Slicing Challenge

Here's the latest version of Cura.

Cap: Links: I thought maybe it's something with your config, so I loaded your config and resliced it. Here's the links layer again (note your zero centered bed):

Cap: Links: I thought maybe it's something with your config, so I loaded your config and resliced it. Here's the links layer again (note your zero centered bed):

Re: Chain Mail Slicing Challenge

That was, alas, the last Slic3r version with good bridges: it produced those big chain mail sheets back in December. I think every version since then produces incorrect bridging.jsc wrote:this is in Slic3r 1.2.1

Looks like I'm stuck at 1.2.1 for the chain mail, which is a shame given all the other improvements. The configuration file format isn't backwards compatible, so it's not just a matter of firing up the proper version as needed.

That's definitely better, but Cura seems to produce each bridge thread with an independent extruder start-and-stop cycle. Anchoring a bridge thread exactly on the perimeter thread(s) requires very, very finicky retraction adjustment; you'd (well, I'd) never notice any problem in a model with fewer bridges.jsc wrote:bridge just the interior gap

Apparently Cura gets confused, too: the topmost link in that image has the infill pattern!

S3D produces each cap with a continuous extrusion that should anchor firmly on the perimeter threads. I like the way that looks.

If you have more spare time than anyone really should, tweak the OpenSCAD code to reduce the links to 4x4 threads (BarWidth and BarThick), set the thread dimensions (ThreadWidth and ThreadThick) to match your extrusion parameters, and see what happens with S3D. Two perimeter threads may squeeze all the infill out of the pillars, but the bridges should be solid.

With 4x4 bars, I used a single perimeter thread to get a smaller patch:

http://softsolder.com/2015/01/12/3d-pri ... r-edition/

Thanks for showing me what's out there...

Re: Chain Mail Slicing Challenge

I don't think you want solid bridges. When they are laid right next to each other, the extruder remelts the neighbor and drags it, causing increased sagging. A somewhat sparser bridge makes for a neater bridge.

Re: Chain Mail Slicing Challenge

The bridging threads look a bit ragged, but there's no evidence of dragging:jsc wrote:A somewhat sparser bridge makes for a neater bridge

In fact, the strands start out droopy and tighten up as they shrink, producing a final result that looks better than I expected. That's why I'm leery of starting bridge threads on just the perimeter threads: given the small anchor area, surely they're more subject to being dragged away, particularly when the nozzle starts next to the end of the thread it just finished laying down.

The bridges run at 50 mm/s and 100% flow; the nozzle doesn't spend much time dilly-dallying over the abyss.

The bars definitely look better than the cap, mostly because the cap spans a larger opening. I think increasing the flow a bit would help with the sparse bars in the cap, but it probably doesn't make any real difference.

The first layer of diagonal infill over the bridges came out fine... whew!