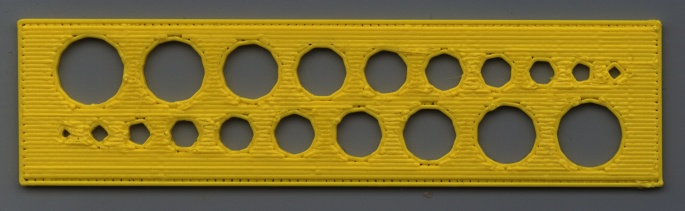

Printed size of circular features

Posted: Wed Feb 25, 2015 7:25 pm

My company purchased an M2 about eight months ago for use in rapid prototyping and printing non-critical plastic parts for machines. First of all let me say that it works GREAT and we are very pleased. However as we print more and more parts, I've noticed that any circular features printed by our M2 seem to be consistently small by about 0.01"-0.03". At first I thought it was just holes, but after doing a little bit of testing it seems like external circular features are small as well - by the same amount. Visually of course, this amount of discrepancy makes no difference. But sometimes we are printing caps to fit snugly around the end of a tube, or clearance holes for bolts. With these kinds of features, 0.01"-0.03" becomes more significant.

What's odd is that it seems to be ONLY circular features that print small. Every rectangular feature the thing prints is right on size, or if there is some variation it deviates more or less randomly from the size in the model. I thought it might be something with the STL export settings in SolidWorks (which I use to make all our models), but I tried downloading and printing this test piece from Thingiverse and it was the same story - the external dimensions were right on but all the holes were too small. http://www.thingiverse.com/thing:35820

We're using Simplify3D to slice the models and run Gcode. I'm attaching a screenshot of my slicer settings. We're using black or white PLA material for the prints.

Has anyone else seen this happen? I realize we could just make the circular features slightly bigger in the model, and/or print plenty of perimeter layers and drill out the holes. But if there's some slicer setting or calibration I'm missing that is the culprit, that would obviously be a better fix. I am still not an expert by any means.

Thanks!

What's odd is that it seems to be ONLY circular features that print small. Every rectangular feature the thing prints is right on size, or if there is some variation it deviates more or less randomly from the size in the model. I thought it might be something with the STL export settings in SolidWorks (which I use to make all our models), but I tried downloading and printing this test piece from Thingiverse and it was the same story - the external dimensions were right on but all the holes were too small. http://www.thingiverse.com/thing:35820

We're using Simplify3D to slice the models and run Gcode. I'm attaching a screenshot of my slicer settings. We're using black or white PLA material for the prints.

Has anyone else seen this happen? I realize we could just make the circular features slightly bigger in the model, and/or print plenty of perimeter layers and drill out the holes. But if there's some slicer setting or calibration I'm missing that is the culprit, that would obviously be a better fix. I am still not an expert by any means.

Thanks!