ChrisERAU wrote:set my tessellation quality to the highest that CATIA allows.

That is probably a mistake, simply because a 3D printer cannot possibly reproduce that much detail. Back it off to 0.01 mm and you won't notice any difference in the results, other than a dramatic reduction in slicing time and probably an improvement in print quality.

Attempting to print extremely small segments causes the G-Code interpreter to pause the nozzle motion, because the USB link simply can't transfer that much G-Code as fast as required. If the linear segments are shorter than about 0.1 mm, you're kidding yourself about the quality: remember, you're creating an object by squishing layers of hot goo atop each other.

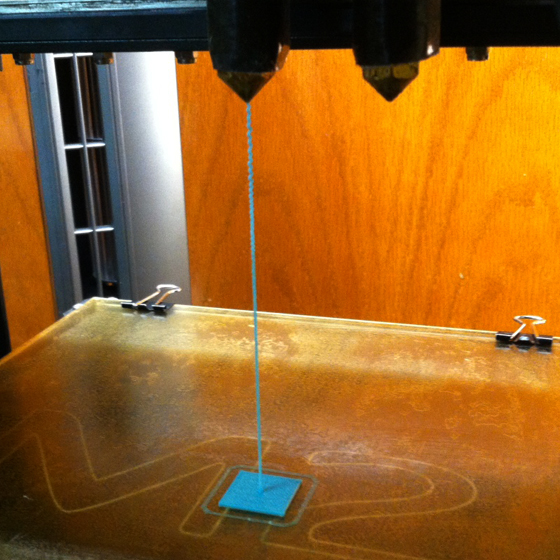

Worse, none of the retraction settings apply to slowdowns due to buffer clogging; the nozzle simply sits there and drools until the interpreter catches up and motion resumes.

Not tight enough (I think) to bend all that steel underneath.

You'd be surprised; less than 100 microns vertically doesn't require all that much bendiness...

However, if the apparent surface is flatter than about 0.10 mm, you're good to go. Split the difference so that the central part is 0.05 mm too short and the outer sections are 0.05 mm too high; you'll have no problem with adhesion or overall print quality.

If the difference is more than 0.10 mm, then trading off adhesion with squashing may be messier. But that definitely isn't causing the stringing problems you're seeing!

Run off a set of five thinwall hollow boxes, measure their heights & positions, and report back! [grin]

http://softsolder.com/2015/09/04/thinwa ... er-images/

My retraction settings are below.

The retraction speed looks low: bump it to 60 mm/s or higher. If it's too high, you'll hear the extruder motor clunk as it skips some steps, which is a Very Bad Thing for print quality. If it's too low, you'll see blobs where the nozzle drools as the hot end pressure gradually drops.

You'll need Z hop (a.k.a. retraction lift) to avoid having the nozzle bump into previously printed objects during travel moves between them. That's more of a problem with thin angled objects than vertical slats, but it'll be obvious when it happens.

the part ends up overheating and the upper layers get a little melty

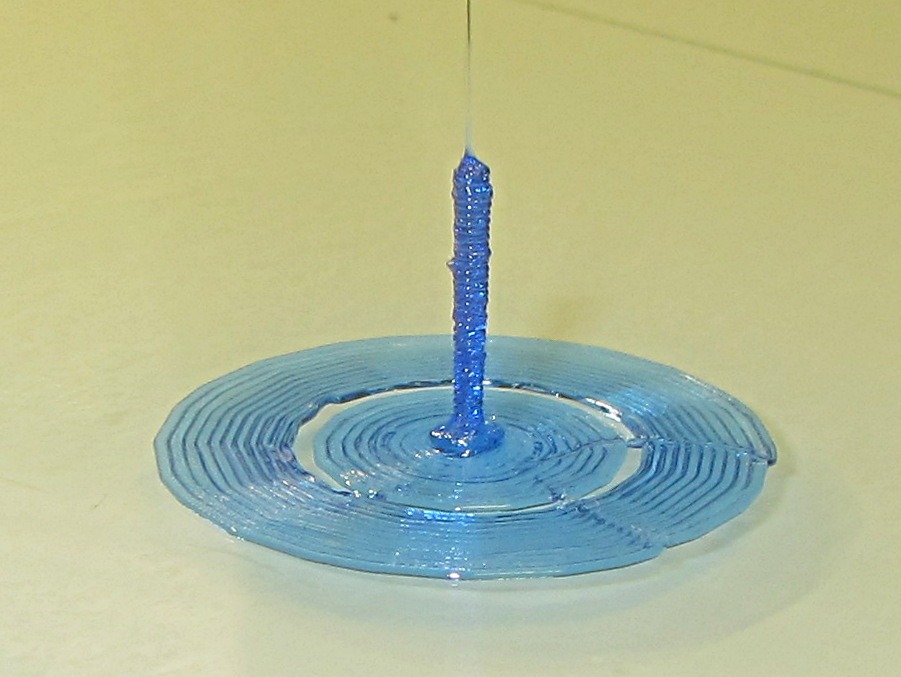

If you can't print a single blade without having it get melty, then your minimum layer time is too low and maybe a few other things need tweaking. I'm using 10 seconds with PETG and this absurdity came out surprisingly well:

viewtopic.php?f=7&t=2985#p19083

A few posts later, Jules trumped everyone:

Bottom line: get

one blade working before you try

six...