Build plate, high spot in the center...

Build plate, high spot in the center...

Anyone tried to shim the rails on your M2? Mine seems to have a high spot in the center of the build plate. Tried a couple new glass plates but with the same results.

Example

https://youtu.be/gMdwH7BvTHA

Example

https://youtu.be/gMdwH7BvTHA

Re: Build plate, high spot in the center...

yes there was just a discussion on here and the person shimmed the rail. the problem is not the glass, its that the x axis has a slight bow down in the middle. quite common. can be from your belt being too tight but not always. check the belt tension and shim the rail to get it right.

Re: Build plate, high spot in the center...

Mine seems to be high in the middle.

Re: Build plate, high spot in the center...

the x axis is high? normally it would have a bow down which would make it like you have a high spot in the middle of your build platform. (glass bowed up)

Re: Build plate, high spot in the center...

Brain fart. Yes, you are correct. The x rail would be bowed down in the middle. Hard to believe the belt could do that on such a hefty frame.

Re: Build plate, high spot in the center...

True but temember we are talking about bowing it 1/8" or anything like that. Its just a micro amount. Just a slight over tension on that belt and using the motor shaft as a lever will be able to make thise kind of slight changes.

- Matt_Sharkey

- Posts: 347

- Joined: Mon Oct 20, 2014 3:10 pm

Re: Build plate, high spot in the center...

We're talking fractions of a millimeter here. The x gantry probably bows a total of 0.10mm from center to edge. Y axis is also subject to this, but less, more like 0.03mmdklassen wrote:Brain fart. Yes, you are correct. The x rail would be bowed down in the middle. Hard to believe the belt could do that on such a hefty frame.

- Matt_Sharkey

- Posts: 347

- Joined: Mon Oct 20, 2014 3:10 pm

Re: Build plate, high spot in the center...

Now I want to go make a test print to see what the bowing is actually equivalent to.Matt_Sharkey wrote:We're talking fractions of a millimeter here. The x gantry probably bows a total of 0.10mm from center to edge. Y axis is also subject to this, but less, more like 0.03mmdklassen wrote:Brain fart. Yes, you are correct. The x rail would be bowed down in the middle. Hard to believe the belt could do that on such a hefty frame.

Re: Build plate, high spot in the center...

I'm deciding now whether 0.12mm is worth messing with. I may try and tweak the belt tension and check the torque of the screws to see if I can effect any change to the better. I don't have any brass shims available at the moment.

Re: Build plate, high spot in the center...

That's more than half the thickness of a 0.20 mm first layer. If you adjust the Z offset so the center threads come out at 0.14 mm (squashed by 0.06 mm), then the edges will be 0.26 mm (0.06 mm too thick) and it'll be OK.dklassen wrote:whether 0.12mm is worth messing with.

If you set the center to "exactly right", then the threads along the platform edges won't adhere: the nozzle will be at 0.32 mm. Those threads will be nice and round and free-floating...

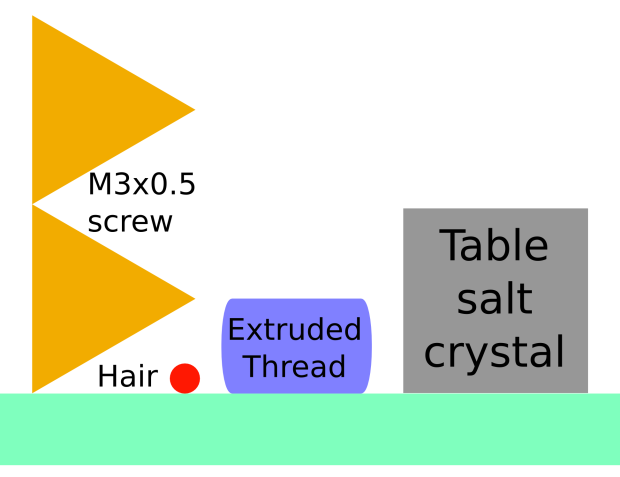

Remember the scale of things on the printer platform:

http://softsolder.com/2015/11/12/3d-pri ... alization/