Max height clearance for M2 Rev. E with v5 hot end?

-

hybridprinter

- Posts: 141

- Joined: Sun Dec 21, 2014 8:04 pm

Max height clearance for M2 Rev. E with v5 hot end?

When using sequential print mode in Simplfy3d, it asks for max height clearance input, does anybody know what it is on the newest machines with v5 hot ends?

-

thunderbt3

- Posts: 105

- Joined: Wed Apr 09, 2014 11:36 pm

Re: Max height clearance for M2 Rev. E with v5 hot end?

V5's already out in the wild? The last I heard, MG said it was in the works.

Re: Max height clearance for M2 Rev. E with v5 hot end?

The problem isn't the hot end, it's the X axis gantry: the tallest possible thing will be the distance from the nozzle tip to the lowest nut.hybridprinter wrote:max height clearance input

In round numbers, that's maybe 5 mm…

You can lie to the slicer and manually position the objects in the proper sequence, but it's not for the faint of heart:

https://softsolder.com/2015/12/28/slic3 ... -printing/

-

hybridprinter

- Posts: 141

- Joined: Sun Dec 21, 2014 8:04 pm

Re: Max height clearance for M2 Rev. E with v5 hot end?

Thanks, so not much benefit to using sequential mode for only 5mm (that's like 16 layers at 0.3mm layer height).

Re: Max height clearance for M2 Rev. E with v5 hot end?

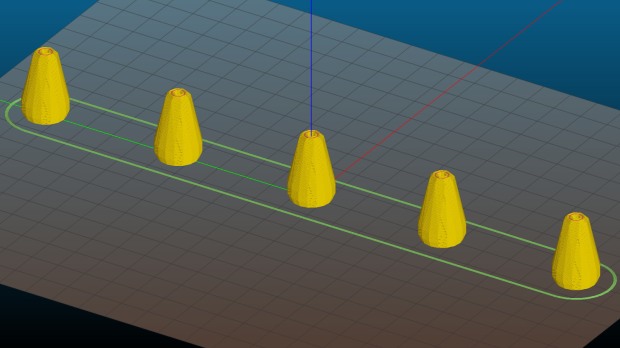

That's where straight-up lying comes in: you set the slicer for oodles of vertical clearance, then manually align the objects front-to-back so nothing (including the front fan!) can hit them.hybridprinter wrote:sequential mode for only 5mm

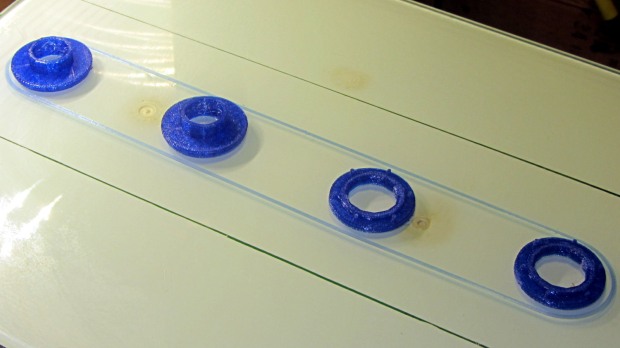

I don't do it often, but it does work. These cord caps stand 25 mm tall:

https://softsolder.com/2016/09/03/miniblind-cord-caps/

They're sequentially printed from -Y to +Y (right to left), so the gantry is always over the empty end of the platform, and I rotated the fans out of the way when I saw what was about to happen.

The only reason for doing sequential printing is to get a good surface finish on many small parts I don't want to print separately; anything else flat-out isn't worth the hassle.

-

hybridprinter

- Posts: 141

- Joined: Sun Dec 21, 2014 8:04 pm

Re: Max height clearance for M2 Rev. E with v5 hot end?

what if you have a couple more rows of parts (rows spaced across the X axis) aligned like that?

Re: Max height clearance for M2 Rev. E with v5 hot end?

You arrange the parts far enough apart in X that the hot end doesn't whack the just-printed part, then arrange the rows far enough apart in Y that the hot end doesn't whack anything in the just-printed row. For example, the parts would print from -X to +X, starting in the row at -Y and proceeding to the row at +Y.hybridprinter wrote:a couple more rows of parts

I could make that work maybe 7 times out of 10, but never on the first attempt…

Remember that the various software previews may not show you the actual build sequence: proceed very carefully, checking your work at every opportunity!