spmahoney78 wrote:maybe my iron wasn't hot enough

Soldering heavy wire requires a high-power iron (or a "soldering gun"), good rosin flux (not acid plumbing flux!), and the conviction you're doing it right. A piddly iron suited for electronic components can't dump enough heat into the wire to raise the temperature fast enough, so you'll cook the insulation and get a cold-solder joint.

Cut off an inch or so on each side of the break to get rid of fretted wire & crumbled insulation. The other wire will be nearly wrecked at that spot, too, so shorten them both. You must see clean shiny copper and no crumbles before you start soldering.

However, rather than solder the old wires, I'd use butt-splice connectors (*) sized for the conductors:

https://www.amazon.com/s/ref=nb_sb_noss ... nector+kit

Again, trim back to good copper, then anchor the connectors to the Y-axis stage so the wires don't flex around them.

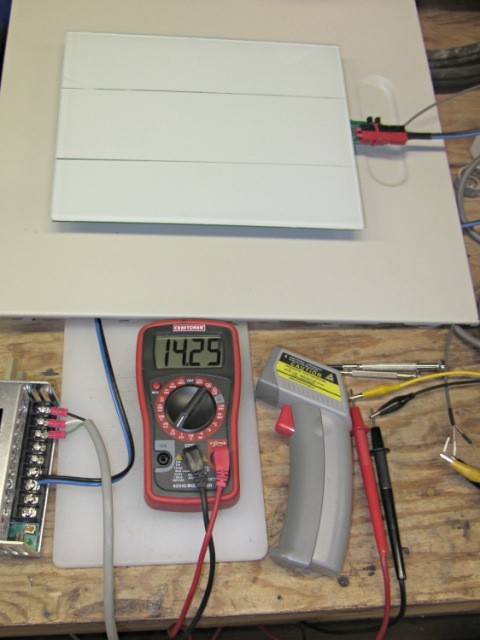

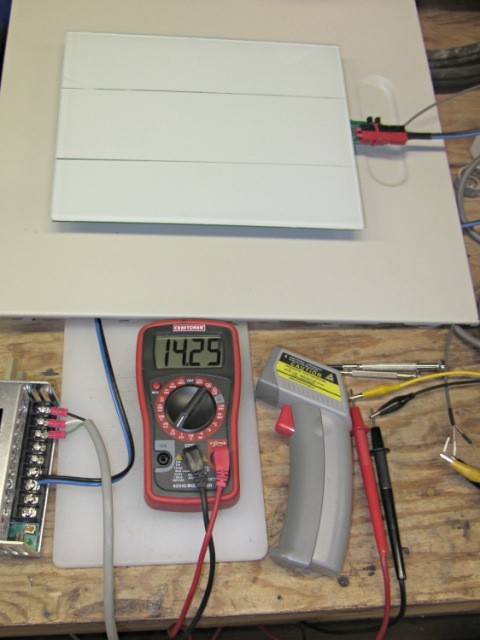

I soldered half an inch of 12 AWG wire onto a hotrod platform for my M2, with crimped Anderson Powerpoles on the cable:

https://softsolder.com/2013/09/05/impro ... rst-light/

That was a "first light" lashup to make sure the platform worked, which it did. Three years later, it's still going strong.

(*) Yeah, that's what they're called. Depending on your "search safety" settings, you may get some NSFW items in the results…