Good Morning,

I thought up a project yesterday to hold supplies that help us reduce central venous line infections in the ICU. I want to print my prototype design, but I have never printed models with threads before. I am not sure how to best orient this and if the supports in the threaded hole are going to cause issues with the threads.

I am considering printing this with the threaded hole side down on the bed but I would still have supports in it to support the end of the clamp.

Here is a screen shot.

Thanks,

jerold

Hole with Threads and Supports

Re: Hole with Threads and Supports

Or would this be a better choice.

Re: Hole with Threads and Supports

Just my $.02 but I wouldn't focus on printing the threads. I'd take the 1st option, rotate it 180° on the Y-axis to eliminate all support and make much smaller pilot holes for proper reaming and tapping.

You're not using Slic3r so I don't know if Cura or S3D has a similar feature...but in Slic3r, I would make a modifier mesh with 100% infill around the area where the finished reamed/tapped hole would be. Then drill and ream to size, and tap the hole.

You're not using Slic3r so I don't know if Cura or S3D has a similar feature...but in Slic3r, I would make a modifier mesh with 100% infill around the area where the finished reamed/tapped hole would be. Then drill and ream to size, and tap the hole.

Re: Hole with Threads and Supports

Size the holes to fit an appropriate knurled brass insert, epoxy 'em in place, and move on:CCRN wrote:printed models with threads

https://softsolder.com/2016/02/03/knurl ... c-inserts/

https://softsolder.com/2016/02/16/knurled-inch-inserts/

You'll get better retention, much better durability, no random plastic fragments, and a good fit. They're cheap & readily available on eBay / Amazon (or spend more at a reputable supplier like McMaster):

https://www.ebay.com/sch/i.html?_nkw=kn ... ass+insert

https://www.amazon.com/s/ref=nb_sb_noss ... ass+insert

Then you can orient the part to get rid of (most of?) the support structures; flip it upside-down to put the smaller flanges on the platform and I think it won't need any supports at all.

Also, don't put supports in the holes. Make them hexagonal, put a flat side on the top so the slicer can bridge it, and a brass insert will make it perfect.

Re: Hole with Threads and Supports

Hi Ed,

So the holes should be sized so the inserts just drop in with epoxy? Or do you put them in when the plastic is still warm?

Thank you,

jerold

So the holes should be sized so the inserts just drop in with epoxy? Or do you put them in when the plastic is still warm?

Thank you,

jerold

Re: Hole with Threads and Supports

That's about the, ah, size of it. I use OpenSCAD with a version of nophead's polyholes() function to produce a hexagon exactly fitting the insert's OD, which makes for a light push fit. Your CAD package probably has a hole generator that does the same thing: make the hole circumscribe the insert and add about 0.2 mm to compensate for small-hole shrinkage:CCRN wrote:holes should be sized so the inserts just drop in with epoxy

http://hydraraptor.blogspot.com/2011/02/polyholes.html

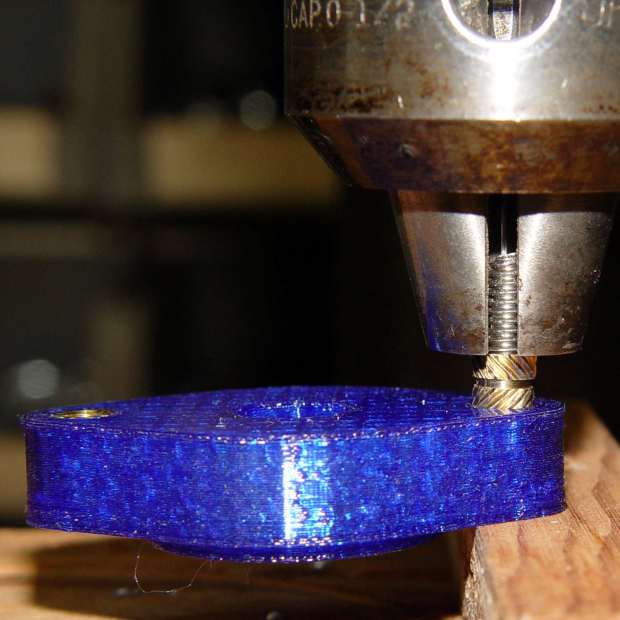

Keeping the hole snug holds the insert in the proper alignment, but I generally thread a stud into the insert and shove it in place with a drill press:

https://softsolder.com/2016/03/07/vacuu ... a-platter/

I tried melting the inserts into smaller holes, which is the way they're supposed to be used with injection-molded parts. Epoxy is less exciting, more consistent, and produces better retention, at least for my one-off parts. It also eliminates the need for specialized and spendy insertion tools.

Re: Hole with Threads and Supports

That helps. Thanks.