Page 1 of 1

Can anyone help identify My problem with my print?

Posted: Sat Mar 09, 2019 4:13 pm

by moesizzlac

Hello all.

Sorry to ask what probably seems like a silly question but I'm lost and I hope some of you can help me figure this out. I have a problem with printing on an angle and i'm not quite sure why.

Setup:

M2

Octoprint to manage the prints

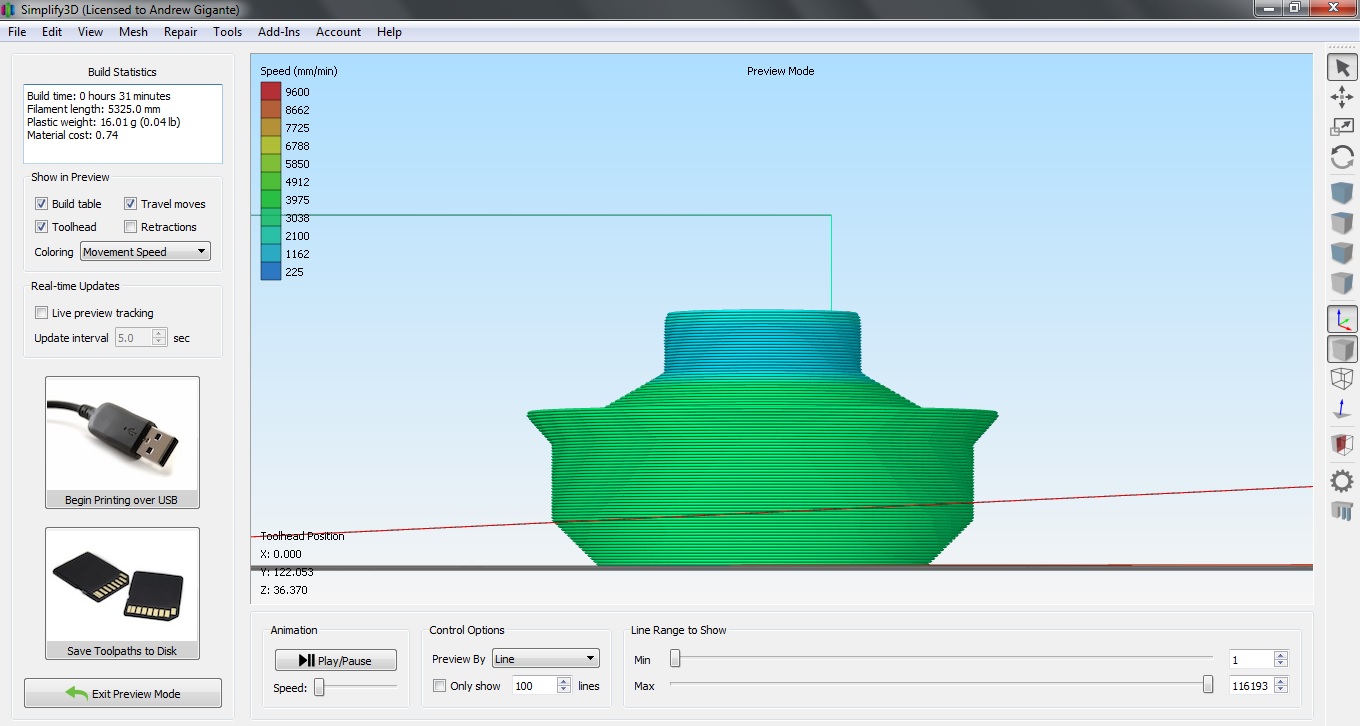

Simplify 3D for gcode

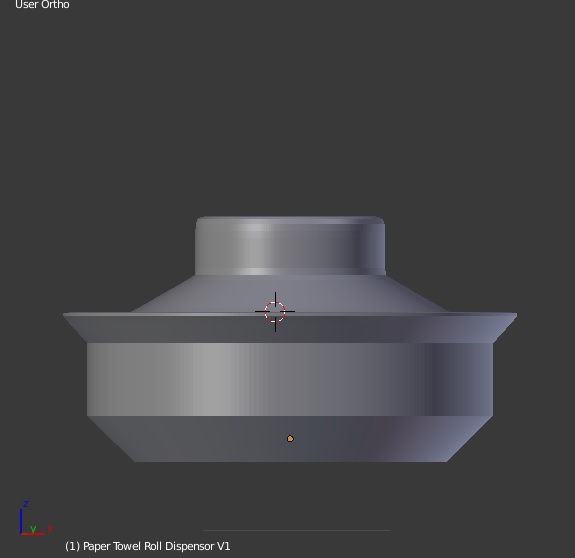

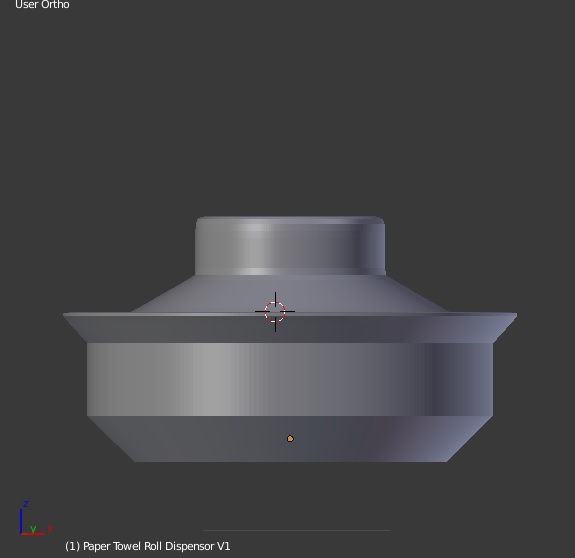

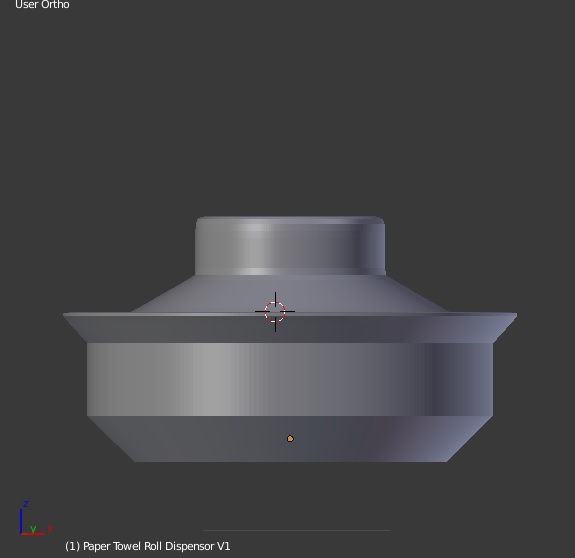

Original design

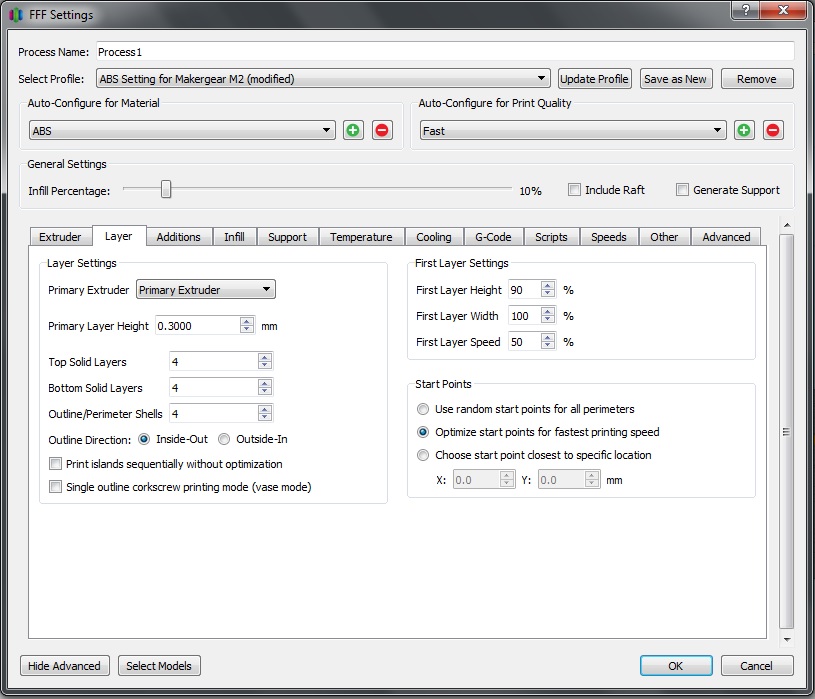

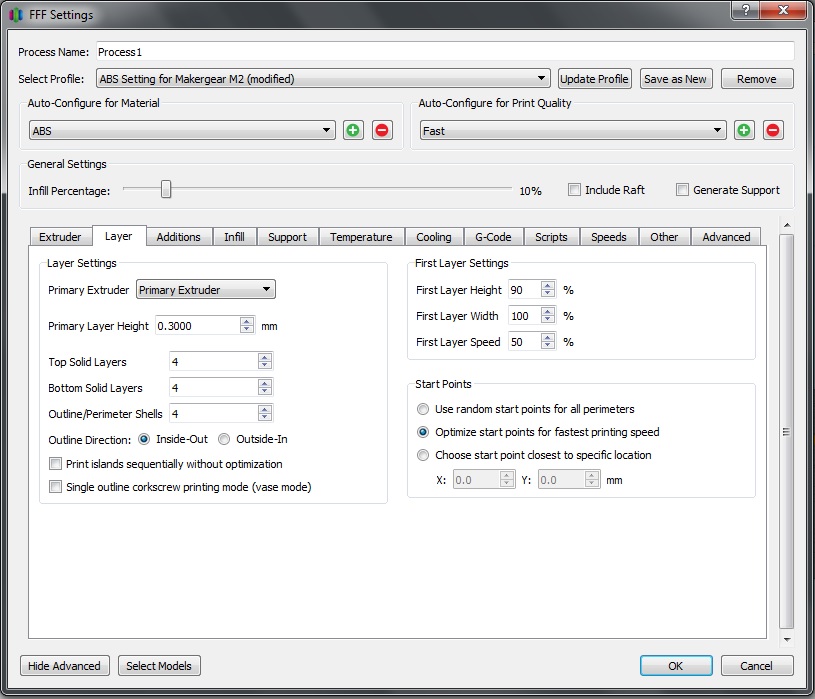

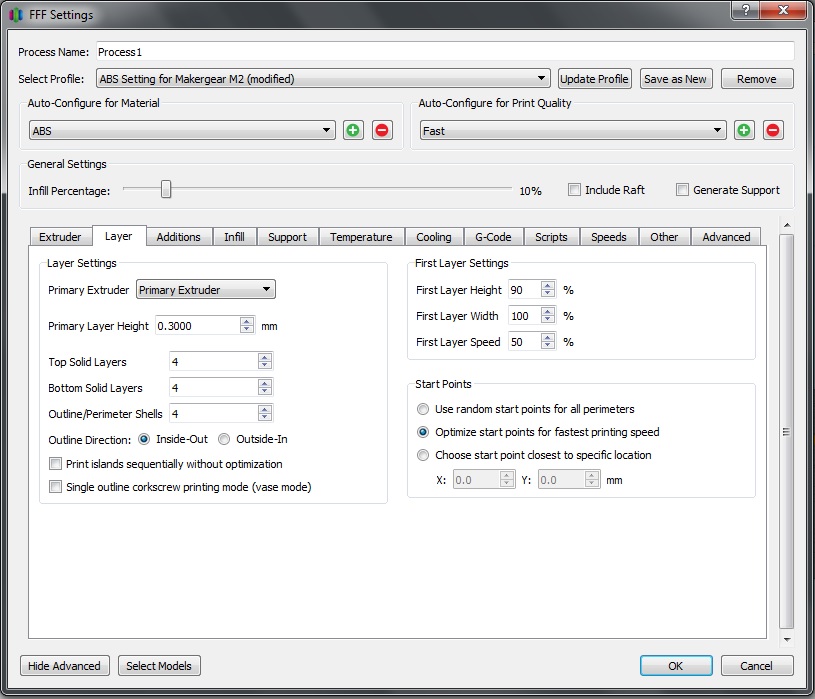

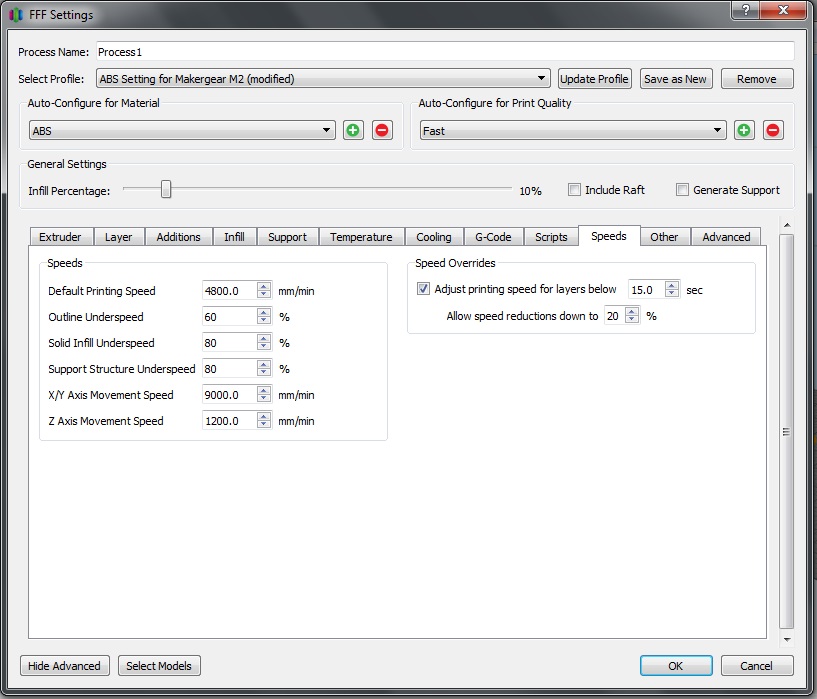

Settings 1

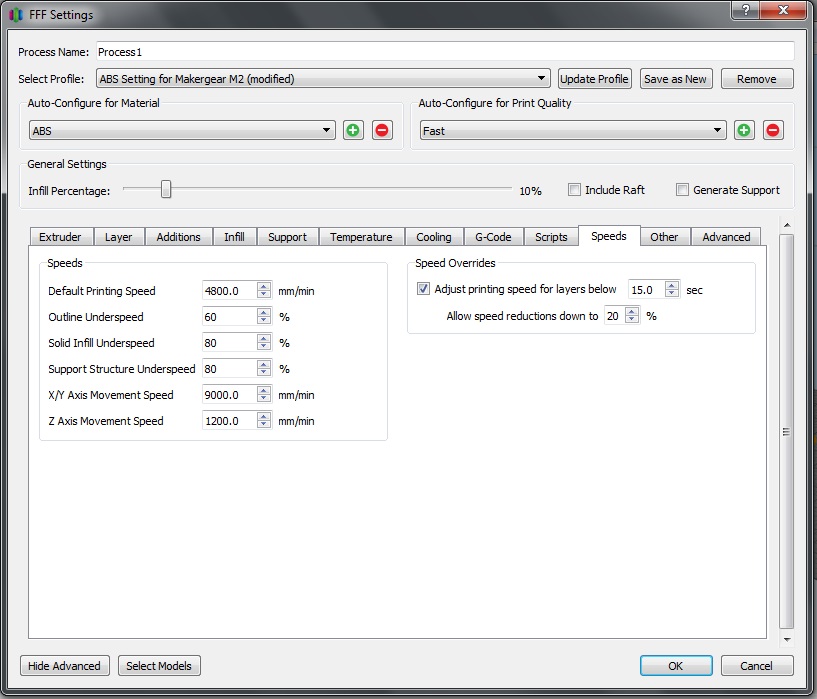

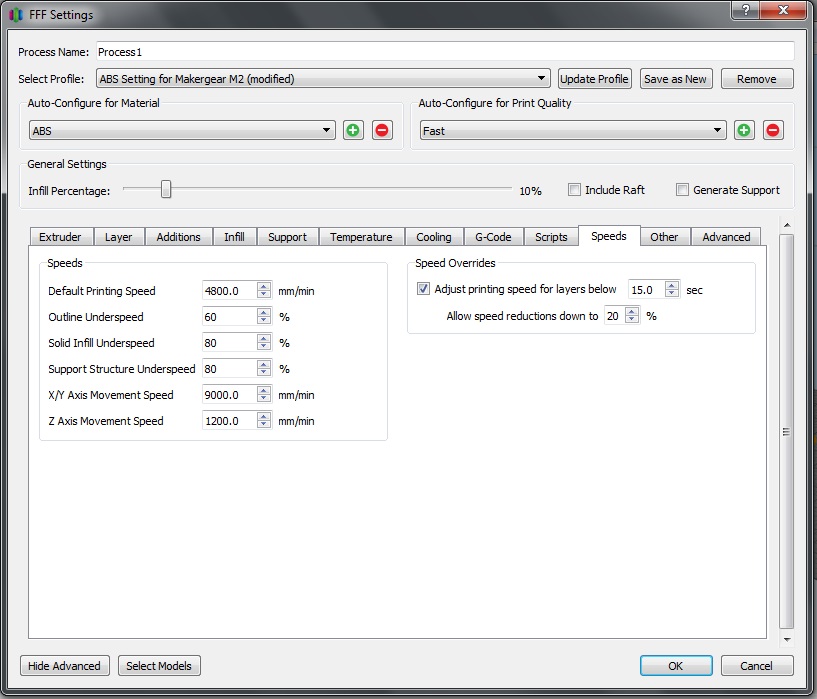

Settings 2

No Supports.

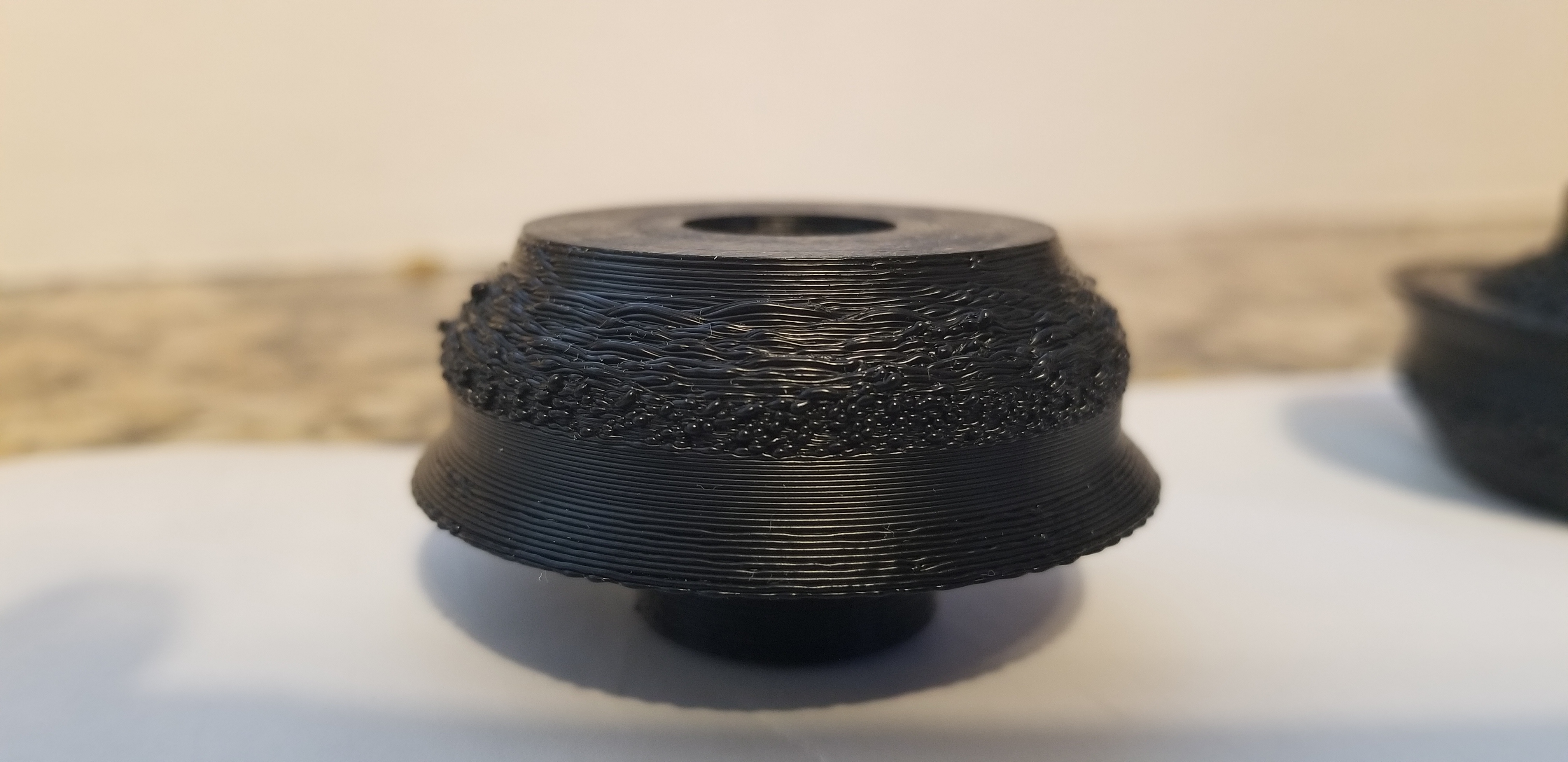

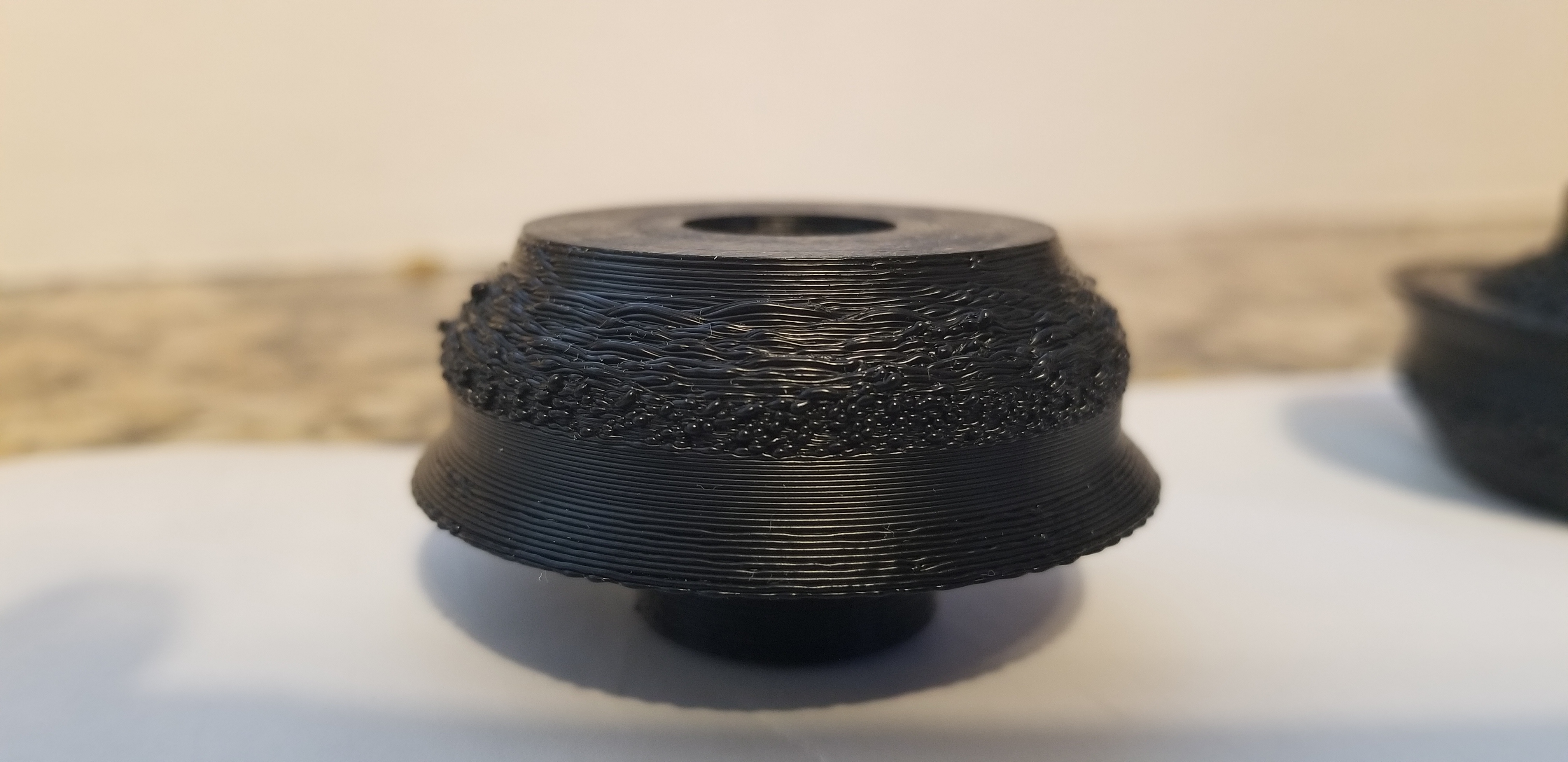

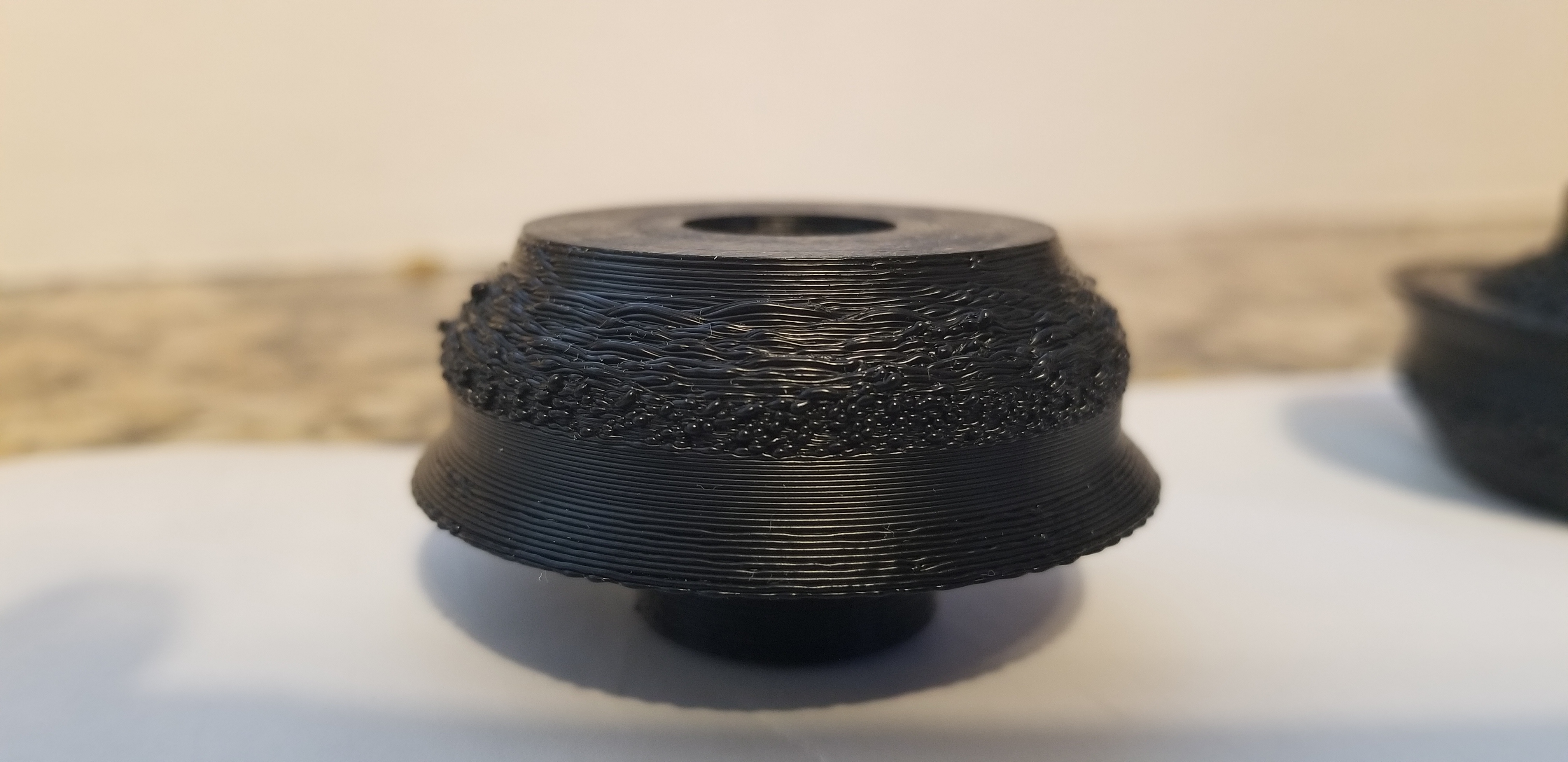

Result 1 - This is the orientation I printed the item:

Result 2

Notice that even printing on the top at an angle results in a similar problem. Is it the 4 layer walls causing this?

I'm pretty sure I'm not over 45 Degree Angle at any point.

Any help is greatly appreciated.

Re: Can anyone help identify My problem with my print?

Posted: Sat Mar 09, 2019 7:00 pm

by ednisley

moesizzlac wrote: ↑Sat Mar 09, 2019 4:13 pm

printing on an angle

The problem most likely has nothing to do with "angles", but more likely with slicer settings or modeling.

First of all, are you

really printing with ABS, as shown in the Auto-Configure dropdown?

Before digging into less likely settings, you may have a non-manifold model producing bizarre slicing errors on those surfaces. Check S3D's guide:

https://www.simplify3d.com/support/arti ... sh-errors/

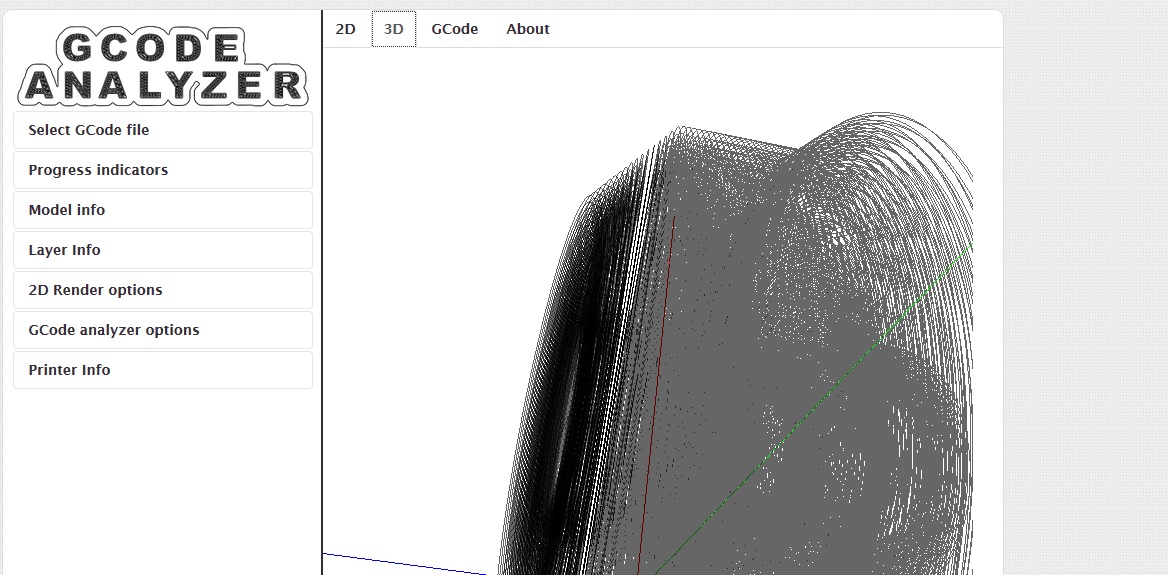

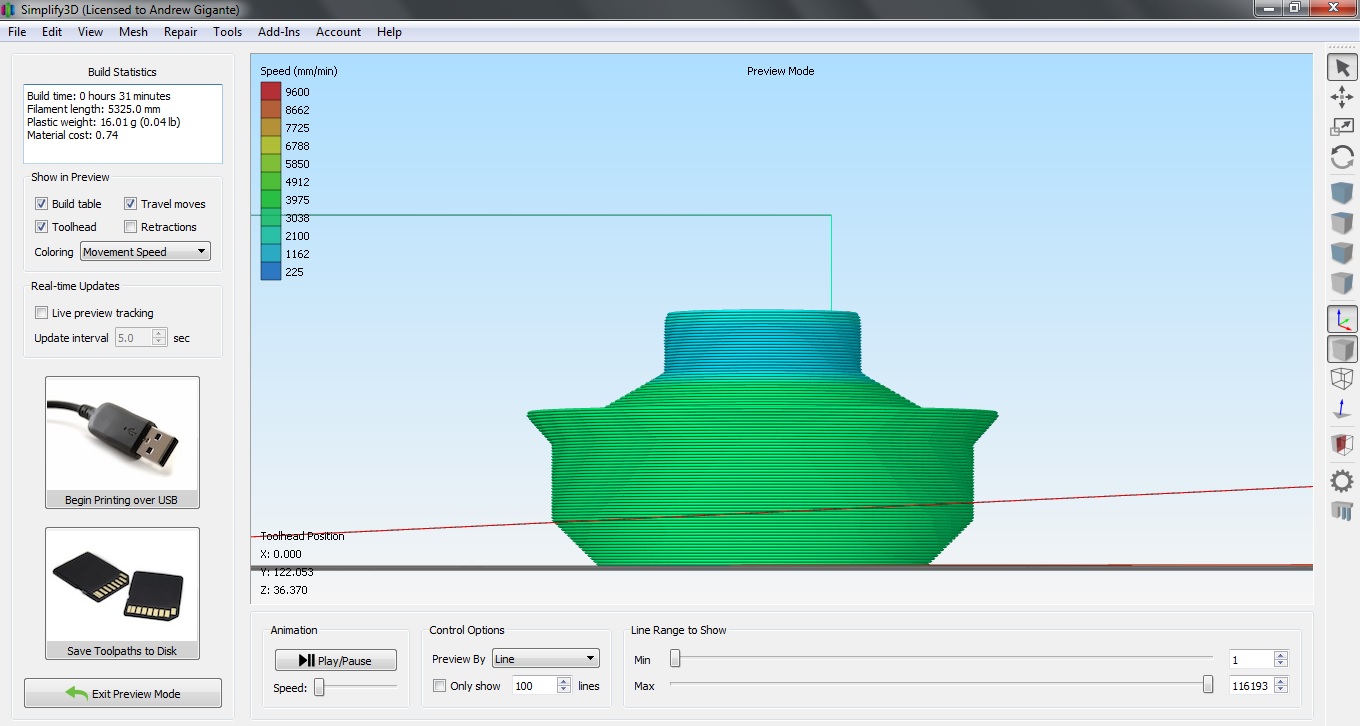

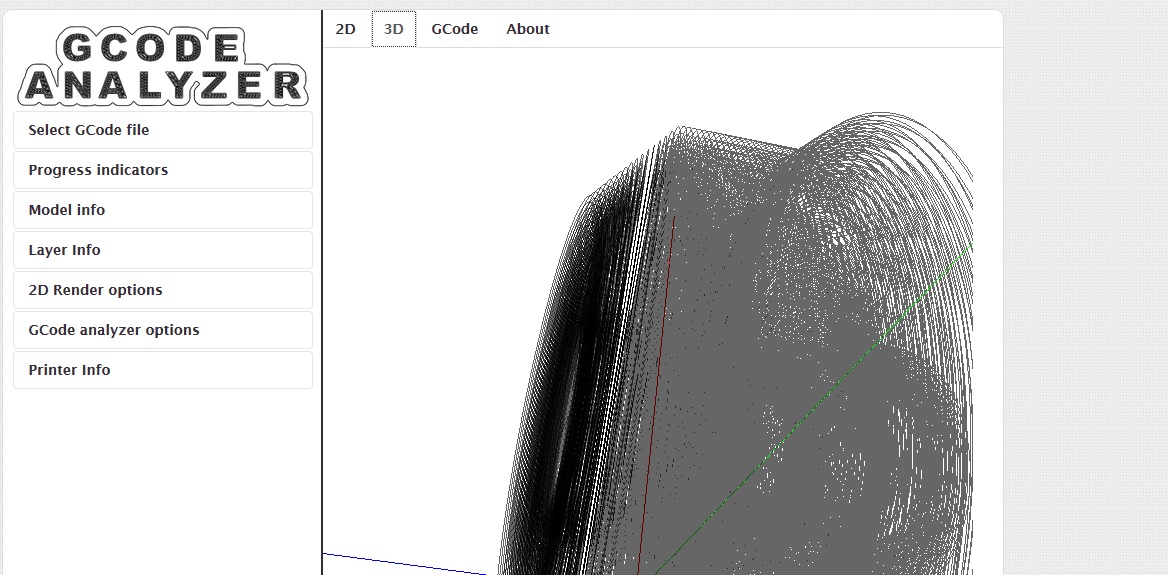

Previewing the G-Code (at, for example,

http://gcode.ws/) provides a sanity check by using a completely different preview algorithm than S3D. If the previews differ, you know something's still wrong, even if not quite what to tweak.

If the model passes inspection, then it's time to look into slicer settings & suchlike.

Re: Can anyone help identify My problem with my print?

Posted: Sat Mar 09, 2019 7:57 pm

by moesizzlac

Thank you Ed for the suggestions.

Using E-Sun ABS Black(

https://www.amazon.com/gp/product/B00MV ... UTF8&psc=1)

G-Code checks out in both the slicer and the online 3rd party

Did a Blender 3D Check and there are no issues like none manifold edges or bad contig. edges and whatnot.

I might try a lower temp extrusion temp or put the fan speed from 60% to 100% on a build and see if that makes the difference.

Thank you for helping me rule out the others! If you have any more suggestions, They are more than welcome!

Re: Can anyone help identify My problem with my print?

Posted: Tue Mar 12, 2019 2:30 pm

by ednisley

In recent weeks, we've seen a whole bunch of "it used to work and now it doesn't" problems, all sliced with more-or-less current versions of S3D, and considerable moaning about problems with various S3D versions.

I use Slic3r, so I have nothing to offer other than the question taught to me by a great engineer: "What's new and different?"

List everything that's changed. Somewhere in that list, you'll find the problem … but you gotta list everything and work through the entire list.

Re: Can anyone help identify My problem with my print?

Posted: Fri Mar 15, 2019 6:53 pm

by moesizzlac

I think I figured out the rippling effect.

Below are 6 different prints changing the outer wall number and the extrusion rate.

You'll notice that they get lower and lower as the extrusion goes down.

It turns out that I get the smoothest finish with the 2 outside walls and 110 extrusion.

It's nice when the model doesn't require any outside wall strength and can be a self standing object. However, I still have to find out the best way to make something with 4 outside walls and minimal rippling.

Re: Can anyone help identify My problem with my print?

Posted: Mon Aug 12, 2019 5:25 pm

by CaptJasper

It's a little late, but I noticed you're printing inside out rather than outside in. You may get less overhang tolerance, but printing the outermost layer first can help to reduce outer layer rippling like that. This setting is located in the "Layer" tab.

Re: Can anyone help identify My problem with my print?

Posted: Tue Aug 13, 2019 4:33 pm

by ednisley

moesizzlac wrote: ↑Fri Mar 15, 2019 6:53 pm

they get lower and lower as the extrusion goes down

Did you measure the actual filament diameter and calibrate the Extrusion Multiplier? If not, then the slicer doesn't know how much plastic it's extruding and will produce poor results.

Rummaging around the forums will unearth a bunch of discussions on how-to-calibrate, but the outline is to put the measured filament diameter in the slicer, print a single-thread square, measure the actual thread width, divide into the desired thread width, multiply the Extrusion Multiplier by the result, and iterate until the actual width matches the desired width. It'll take one or two iterations, so it's not a big deal, and will clear up a bunch of other problems.