HI All

Having trouble trying to figure out the difference between start code and the code produced when you slice a file. Some people have suggested using a start code and an end code. I have copied and pasted a couple. I like the extra control. However, i am having problems with the Z axis... when i start a print the hot end is off the bed and extruding into mid air...how to i make sure it is the right height for printing?

start code vs slicr3 code

Re: start code vs slicr3 code

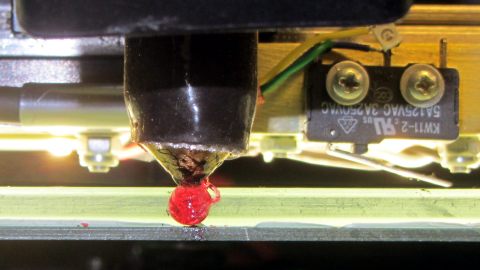

Ah, this is what is known as a "purge cycle" and is written into the start code. The extruder moves off to the right side of the bed and yes, it extrudes into mid-air. After it extrudes a length of filament, it should return to the home position at the corner of the bed, then proceed to the print. The purge cycle ensures that the filament is flowing, because otherwise, from a power-on start, it can take a while for the melted plastic to build up pressure in the nozzle, resulting in some portion of your first layer not printing at all. Even with the purge, sometimes it takes a few seconds from the time the print starts before the filament is flowing properly, which is why most people set their slicers to print a 1-layer thick, 1-filament wide skirt around the base, separated from the printed part by maybe 5mm or so (this is in the "skirt/brim" settings in the slicer). Not only does this help get the filament flowing continuously and smoothly, but it also lets you know if you've done something unfortunate such as position your print halfway off the bed.Kaspa3 wrote:when i start a print the hot end is off the bed and extruding into mid air...how to i make sure it is the right height for printing?

Re: start code vs slicr3 code

The final G-Code file produced by the slicer contains three sections:Kaspa3 wrote: the difference between start code and the code produced when you slice a file

- Printer setup = "start" G-Code

- Object = 3D model from STL file

- Printer shutdown = "end" G-Code

The "Object" part of the file contains only the G-Code required to produce the 3D model in plastic. Those instructions produce the layers by tracing around the outline, filling the interior, and so forth, using the temperature / speed / size parameters you've defined. The slicer assumes the printer is ready to run at the first instruction, so it simply plunks these instructions into the output file after the start block.

The "Printer shutdown" stage turns off the heaters, positions the platform, moves the extruder out of the way, and does whatever else might be needed to stop printing. The slicer produces that by copying another fixed block of G-Code (again, with substitutions) to the output file.

The G-Code instructions in both the start and end G-Code blocks must match the printer hardware and firmware configuration, so copying those files from somebody else may not produce the results you expect and can, in fact, seriously crunch the printer hardware.

Although the startup G-Code for my bizarre setup definitely won't work for you, the line-by-line walkthrough may be informative:

http://softsolder.com/2015/03/31/makerg ... -whatever/

As a rule of thumb, don't change anything in the start or end G-Code files unless you're really, really sure you know what the new instructions will do. Even then, watch it carefully with a finger on the Reset button... because Stuff Happens. [grin]

Re: start code vs slicr3 code

thank you Ed! I feel like I am light years ahead of where I was just 24 hrs ago because of your input!! will try and find some success stories on ABS and let you know how I make out...Thank you

Re: start code vs slicr3 code

Yeah Ed definitely has his own way of doing things but does a great job steering people towards the right answersKaspa3 wrote:thank you Ed! I feel like I am light years ahead of where I was just 24 hrs ago because of your input!! will try and find some success stories on ABS and let you know how I make out...Thank you

Custom 3D printing for you or your business -- quote [at] pingring.org

Re: start code vs slicr3 code

Aye: there's the right way, the wrong way, and my way... [wince]