Warts and Seams

- pyronaught

- Posts: 684

- Joined: Mon Dec 01, 2014 8:24 pm

Re: Warts and Seams

I'm beginning to think the wart problem on curved geometry with no natural seams to hide them in is another artifact that can't be gotten rid of 100% except by using very slow speeds. It seems like the abruptness of the reversal in direction plays a role in this. I haven't tried super low acceleration settings via the M201 code yet, currently it is set to 800. I don't notice any kind of a slowdown at all though, it just seems to hit the end and instantly jolt back in the opposition direction. Perhaps the momentum from this is enough to sling plastic slightly, or perhaps it jolts the machine and the resulting vibration causes plastic to be deposited along the line that the vibration is occurring in. I've noticed that there are usually gradually diminishing streaks heading off the warts going in the direction that the extruder is moving after the reversal. Maybe this is related to the same phenomenon creating the ghosting of cutout profiles on edges where the head reverses direction. The wart problem seems to be worst on cylinder walls, which would make sense if my above theory is true. A vibration is going to cause movement along a straight line which would not conform to the curvature of the cylinder wall, whereas if printing a wall that is parallel to the X axis the warts are almost invisible. In the 2nd image above where there is a cylinder joined to a box, the box has no warts on the sides but has them on the rounded corners and the cylinder has them all over. So if a direction change occurs on walls both parallel and perpendicular to the X axis (extruder axis), no wart is generated.

Experience is what you get when you didn't get what you wanted.

Re: Warts and Seams

yeah 100% no but you should be able to get it mostly under control. i prefer a seam rather than scattered across my model. there is even a seam in injection molded parts so as long as i get my settings right and get the seam so its fairly insignificant then im ok with that. the bumps may be exaggerated on a cylinder type surface as you say but they are from one thing and that is oozing from the hot end. no ooze then no bump. i wish i had my old v3b abs profile i could give you. once i went with the e3d i got rid of them. if i remember right though i had retraction around 2.8mm, coast was 2.4 and restart was at -.05 or -.1. cant remember exactly. the v3b hot end has a long hot zone. there is alot more molten material in it than newer hot ends so it requires higher ooze control settings than probably the v4 or my e3d which have short and sharp hot zones. again, alot of this has to do with the plastic you are running as well. everything down to brand, color, moisture content and the formula of the abs that the company uses to make their filament. i have had some abs that can sit in the hot end not printing and barely anything comes out while others sit there for a min and i have an inch of curly q's hanging from the nozzle.

- pyronaught

- Posts: 684

- Joined: Mon Dec 01, 2014 8:24 pm

Re: Warts and Seams

I set M201 acceleration down to 400 and am still getting blobs even though the speeds are noticeably slower on the stops and starts at the wart spots, so it's not a speed thing. I've got coast all the way up to 3 now but still getting warts, it's almost like coast has no effect, or the ooze rate is just so high that no amount of coasting can stop it. I'm testing with MakerGear black ABS, since that seems to have the worst wart problem.

So other extruder types don't have this problem? I see these various extruder types mentioned here but have not researched them. I was wondering which one is best or what the tradeoffs are with them. The names are so cryptic it's hard to keep them straight, why couldn't they use easier to remember names instead of v3b and e3d? Are these extruders designed by MakerGear or is this an open source third party type of thing? I noticed the RepRap machines have a radically different looking extruder with a large printed spur gear on it.

So other extruder types don't have this problem? I see these various extruder types mentioned here but have not researched them. I was wondering which one is best or what the tradeoffs are with them. The names are so cryptic it's hard to keep them straight, why couldn't they use easier to remember names instead of v3b and e3d? Are these extruders designed by MakerGear or is this an open source third party type of thing? I noticed the RepRap machines have a radically different looking extruder with a large printed spur gear on it.

Experience is what you get when you didn't get what you wanted.

Re: Warts and Seams

Hotends are hard to make, that's why everybody makes one (since theirs is "the best").

MakerGear has their own series of hotend, the MakerGear Plastistruder hotend. It's been through several iterations (3.5) with the 4th coming out soon.

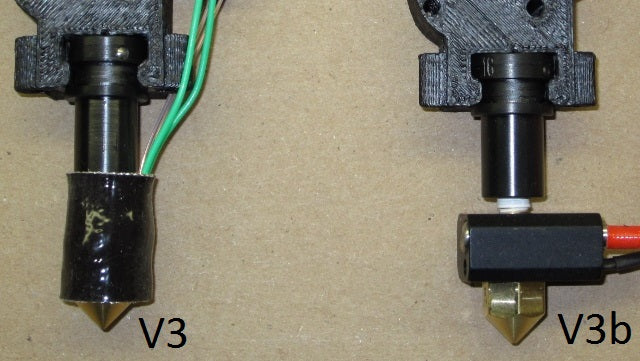

Here's the V3 (which I don't think was a huge change from the v2):

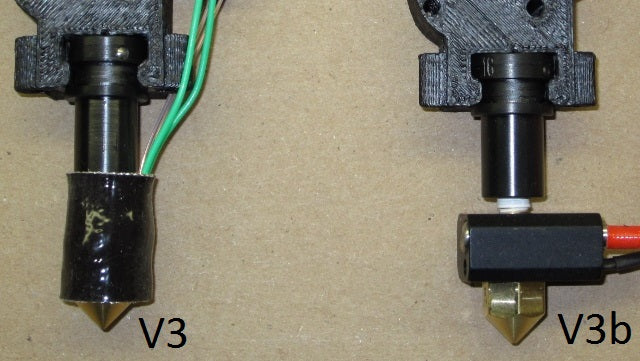

Here's the V3 next to a V3b:

They called it a V3b instead of a V4 or something because the internal geometry didn't change, just the way heat was applied. They didn't feel it justified a new version number, so it didn't get one. The V4 is a radically new design coming out soon.

-----

Ooze is caused by several factors, but the vast majority of it is the quality of plastic. Yours is probably moist, however drying it is hard. You have to heat it hot enough to drive the water out (90C) without melting the plastic (60C). Good luck.

MakerGear has their own series of hotend, the MakerGear Plastistruder hotend. It's been through several iterations (3.5) with the 4th coming out soon.

Here's the V3 (which I don't think was a huge change from the v2):

Here's the V3 next to a V3b:

They called it a V3b instead of a V4 or something because the internal geometry didn't change, just the way heat was applied. They didn't feel it justified a new version number, so it didn't get one. The V4 is a radically new design coming out soon.

-----

Ooze is caused by several factors, but the vast majority of it is the quality of plastic. Yours is probably moist, however drying it is hard. You have to heat it hot enough to drive the water out (90C) without melting the plastic (60C). Good luck.

Custom 3D printing for you or your business -- quote [at] pingring.org

Re: Warts and Seams

v3b is what you have now. e3d is another company all together. i am talking about just the hot end here. not the whole extruder. yes all printers ooze. its the nature of the beast. the newer hot end designs though like makergears new v4 which is still in beta i believe, the e3d i have and many others have moved to a shorter hot zone. they still ooze but its just a little easier to control. the more you lower you acceleration the worse it will get because it takes longer to get the nozzle to the destination which allows more plastic to ooze. as xy movement speed and acceleration decrease then the ooze control #'s need to increase. just something to check here....pull the filament drive off your extruder and check to make sure the drive gear is tight. its a super tiny allen screw. it can loosen up and give poor print and ooze control. if it is all tight take a fine sharpie and put a line from the shaft across onto the gear so you can visually see if they become loose and misaligned. also twist the gear back and forth to be sure there is no rotational slop in the shaft. the repraps you see with the big gear are not always but usually a bowden style extruder.

- pyronaught

- Posts: 684

- Joined: Mon Dec 01, 2014 8:24 pm

Re: Warts and Seams

Maybe I'll just wait for V4 if it is close. I see there are several companies selling the E3D, but they all look like 12v versions. I'm not sure if my machine is 24V or 12v because the power supply is not labeled.

I'm up to 6 mm on the coast now and only just starting to see wart reduction. The ghosting cutout problem is starting to diminish as the warts diminish, so it must be related.

I'm up to 6 mm on the coast now and only just starting to see wart reduction. The ghosting cutout problem is starting to diminish as the warts diminish, so it must be related.

Experience is what you get when you didn't get what you wanted.

Re: Warts and Seams

The big gear is usually a Greg's Accessible Wade's extruder, which is almost always direct drive...jimc wrote:v3b is what you have now. e3d is another company all together. i am talking about just the hot end here. not the whole extruder. yes all printers ooze. its the nature of the beast. the newer hot end designs though like makergears new v4 which is still in beta i believe, the e3d i have and many others have moved to a shorter hot zone. they still ooze but its just a little easier to control. the more you lower you acceleration the worse it will get because it takes longer to get the nozzle to the destination which allows more plastic to ooze. as xy movement speed and acceleration decrease then the ooze control #'s need to increase. just something to check here....pull the filament drive off your extruder and check to make sure the drive gear is tight. its a super tiny allen screw. it can loosen up and give poor print and ooze control. if it is all tight take a fine sharpie and put a line from the shaft across onto the gear so you can visually see if they become loose and misaligned. also twist the gear back and forth to be sure there is no rotational slop in the shaft. the repraps you see with the big gear are not always but usually a bowden style extruder.

Custom 3D printing for you or your business -- quote [at] pingring.org

Re: Warts and Seams

If there's only one, with a MakerGear logo in the plastic case, it's a 24 volt machine. The previous version used TWO bricks (one was a Dell brick from some PC thing). The first brick was 12 volts, for the bed heater, and the other was 19 volts, for everything else.pyronaught wrote:... I'm not sure if my machine is 24V or 12v because the power supply is not labeled.

Dale

- pyronaught

- Posts: 684

- Joined: Mon Dec 01, 2014 8:24 pm

Re: Warts and Seams

At the slower speed I can see that the blob occurs at the end of the tool path and is present before the retraction ever takes place. It really seams like the coasting feature is just not working, even though the preview is showing the empty slots where coasting takes place. I wonder if the blob is actually an accumulation that happens on the outside of the nozzle and is just pushed ahead and then finally deposited when the direction is reversed. I'm at 7mm coast and still getting blobs, which seems unreasonable.

Experience is what you get when you didn't get what you wanted.

- pyronaught

- Posts: 684

- Joined: Mon Dec 01, 2014 8:24 pm

Re: Warts and Seams

I have the 24v one then, it's just a single unit with the M2 logo on it. I wonder why they don't make a 24v E3D, or at least make it an option on the order form. Is M2 the only 24v machine or something?Dale Reed wrote:

If there's only one, with a MakerGear logo in the plastic case, it's a 24 volt machine. The previous version used TWO bricks (one was a Dell brick from some PC thing). The first brick was 12 volts, for the bed heater, and the other was 19 volts, for everything else.

Dale

Experience is what you get when you didn't get what you wanted.