jsc wrote:the difference between model coordinates and machine coordinates

Maybe I'm blind to that difference, but ...

In the normal case, model coordinates have Z=0 at the bottom surface of the geometry. Aligning the machine coordinates so that the mechanical Z=0

also occurs at the bottom surface of the printed plastic part seems entirely reasonable: measure 1 mm from the bottom surface and you're at the same position in both model and plastic.

With the origins matched, 1 mm above the base of the model means 1 mm above the platform: the model coordinates equal the G-Code coordinates and both of those equal the actual physical position. If you measure the plastic and it doesn't match what you see in the G-Code,

it's obviously wrong.

the plastic itself begins at z=0

The layer thickness depends on the slicer settings,

not the model or the machine. You will use different layer thicknesses for different models, so defining the mechanical Z=0 position to be, say, one 0.25 mm layer above the platform will produce an

incorrect first layer for models sliced with (say) 0.10 mm layers, unless you compensate for that mechanical setting with a first-layer slicing adjustment of some sort.

With the mechanical Z=0 position at the platform surface, changing the layer thickness doesn't require

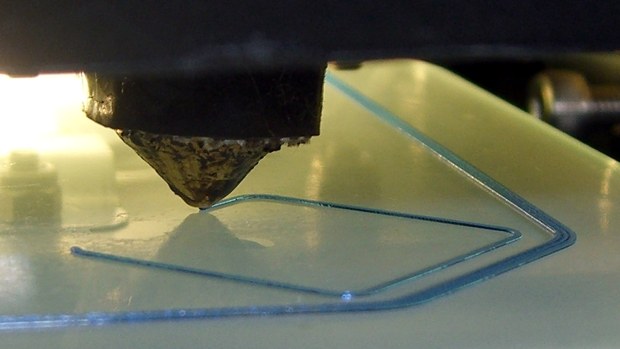

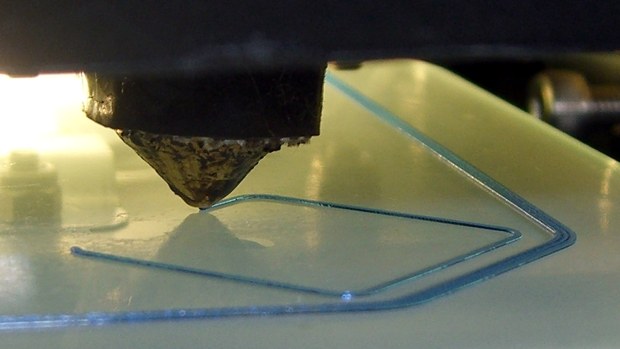

any compensation for different layer thicknesses. The nozzle simply moves to the appropriate Z-axis coordinate and poots out a plastic layer with exactly that thickness.

So, for example, this 0.25 mm first layer happened because that was the slicer setting:

https://softsolder.com/2015/09/04/thinw ... er-images/

I can measure that layer, compare it with the G-Code, compare it with the slicer settings, and compare it with the model: all (should) have exactly the same numeric value.

Using 0.10 mm layers requires changing

one slicer setting,

with no other changes. The G-Code for the first layer would contain Z0.1, rather than Z0.25, and that's what the machine would produce. Well, ideally, of course ... [grin]

With aligned coordinates, you enter

exactly what you want the first layer thickness to be, without the mental gymnastics required to adjust for the mechanical offset or figure the sign of the adjustment or recall what the firmware stored for the layer thickness of a long-forgotten model.

Yes?