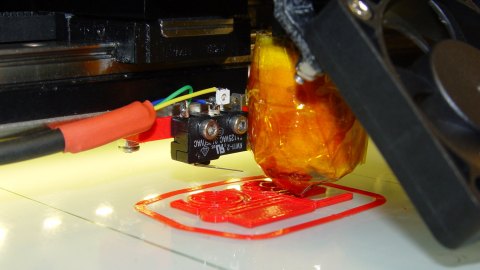

thread-locking insert for Z-stop screw

thread-locking insert for Z-stop screw

I wish the M2 has a tapped hole with thread-locking nylon insert so that the Jam nut could be permanently retired. I'm not quite ready to start drilling mine out but if there are any Makergear-designers listening, This would sure be a huge timesaver

(This embedded in the platform itself

http://www.mcmaster.com/#90250a024/=w3xe9i

And this thumbscrew, fed fromt he underside so that Z-could be adjusted precisely by hand (choose whatever length assured clearance)

http://www.mcmaster.com/#90200a549/=w3xgzb

(This embedded in the platform itself

http://www.mcmaster.com/#90250a024/=w3xe9i

And this thumbscrew, fed fromt he underside so that Z-could be adjusted precisely by hand (choose whatever length assured clearance)

http://www.mcmaster.com/#90200a549/=w3xgzb

Last edited by BigBadBry on Sun Mar 01, 2015 12:25 am, edited 1 time in total.

Re: threaded locking-insert for Z-stop screw

Seems like there is enough space between the plate and the z-stop that you could fit a printed plastic part in there that screwed down with the M4, and allowed a second bolt to screw directly into the ABS. I wonder if the ABS (or your filament of choice) acts similar to any nylock material, ie would keep the bolt position regardless and absorb vibrations etc.

Easier to model it than to describe it: http://i.imgur.com/mHv2Uug.jpg

Bolt head slides in, and fits into a recess, allowing the whole piece to be turned to tighten it. Add a locking bolt on the bottom to keep it super secure, so turning the second bolt won't loosen it.

Edit: With the standard/v3b setup, this part would be way simpler. The bolt that locks the plastic part to the plate doesn't have to be in the same axis as the adjustable bolt - as you can rotate the z-stop around. I upgraded to the v4, which has a much fancier/nicer zstop holder, but is situated directly over the threaded hole. It might be possible to offset them if you used on of the knurled large-head bolts you mentioned, then its really just a plain block with a 4mm hole, and a separate hole for the adjustment bolt.

Easier to model it than to describe it: http://i.imgur.com/mHv2Uug.jpg

Bolt head slides in, and fits into a recess, allowing the whole piece to be turned to tighten it. Add a locking bolt on the bottom to keep it super secure, so turning the second bolt won't loosen it.

Edit: With the standard/v3b setup, this part would be way simpler. The bolt that locks the plastic part to the plate doesn't have to be in the same axis as the adjustable bolt - as you can rotate the z-stop around. I upgraded to the v4, which has a much fancier/nicer zstop holder, but is situated directly over the threaded hole. It might be possible to offset them if you used on of the knurled large-head bolts you mentioned, then its really just a plain block with a 4mm hole, and a separate hole for the adjustment bolt.

Re: threaded locking-insert for Z-stop screw

take your m4 z screw, put the jam nut on it and thread it in from the bottom up. then take a m4 nylock nut and screw it on the tip of the bolt so its 1/2 way bedded into the nylon lock. adjust the bed gap so its really close and tighten the jam nut. all you need to do now to make most fine adjustments is turn the nut on top. 1/2 a flat on the nut is aprox .05mm. i use a little 7mm wrench and i can reach right in where ever the bed may be and make my adjustments without touching the bolt or jam nut at all. it quick and easy.

Re: threaded locking-insert for Z-stop screw

You can relocate the switch to the gantry, measure the offset from switch to nozzle once, plug that into the slicer, remove the Z bolt, and be done with it. Because the switch measures the actual platform position, it gets the right answer after you realign the platform, too.BigBadBry wrote:a huge timesaver

This requires a bit of tinkering with the startup G-Code to move the nozzle off the platform before homing Z, so it's not a drop-in replacement:

http://softsolder.com/2013/10/14/makerg ... in-switch/

http://softsolder.com/2013/11/04/makerg ... ht-switch/

The switch hangs a bit too low for the V4 hot end, so I'm silver-soldering a bracket to replace the red plastic mounting block. The basement shop is way too cold for long sessions, though, and I haven't gotten it properly fixtured yet.

Re: threaded locking-insert for Z-stop screw

Hi Jimc,

Have you seen if the nut "move" over time? Since the nut on top is not tight firmly, it could theoretical move from the vibrations of the machine. I was thinking about doing something like this, as tighten the bolt and lock nut is infuriating. I have 2 m7 wrenches such that the bolt doesn't move when I tighten the lock nut, but some how it always does and I lost my ~ .006mm gap. That is why I was asking about the g-code offset as it seems like a good alternative if you get the gap really close and use the software to make up the difference.

Mike

Have you seen if the nut "move" over time? Since the nut on top is not tight firmly, it could theoretical move from the vibrations of the machine. I was thinking about doing something like this, as tighten the bolt and lock nut is infuriating. I have 2 m7 wrenches such that the bolt doesn't move when I tighten the lock nut, but some how it always does and I lost my ~ .006mm gap. That is why I was asking about the g-code offset as it seems like a good alternative if you get the gap really close and use the software to make up the difference.

Mike

jimc wrote:take your m4 z screw, put the jam nut on it and thread it in from the bottom up. then take a m4 nylock nut and screw it on the tip of the bolt so its 1/2 way bedded into the nylon lock. adjust the bed gap so its really close and tighten the jam nut. all you need to do now to make most fine adjustments is turn the nut on top. 1/2 a flat on the nut is aprox .05mm. i use a little 7mm wrench and i can reach right in where ever the bed may be and make my adjustments without touching the bolt or jam nut at all. it quick and easy.

Re: thread-locking insert for Z-stop screw

mike, there is no movement with a nylock nut. i need a wrench to turn it. if its fully bedded in the nylon lock i cant turn it with my fingers.....usually. i have had mine like this since day 1. its been over a year and a half now. i couldnt imagine having the bolt any other way.

Re: thread-locking insert for Z-stop screw

Its a little tricky but you can also put the locknut upside down (nyliner first). the locking effect is the same, and youd have a much flatter end to work with.. Not quite as nice and smooth as a hex head I'm sure

As a dirty alternative,. has anyone considered overloading teflon tape onto the tip of the stock bolt. despite it being a lubricant, it makes a pretty tight fit that, when packed in there, wouldn't easily move.

As a dirty alternative,. has anyone considered overloading teflon tape onto the tip of the stock bolt. despite it being a lubricant, it makes a pretty tight fit that, when packed in there, wouldn't easily move.

Re: thread-locking insert for Z-stop screw

yes you can do that. i however have never found it necessary to move the nut more than a half turn in either direction. once the bolt and jam nut are set really close then it doesnt take much to tune it in.

Re: thread-locking insert for Z-stop screw

ok, now THIS would have been an AWESOME stock part to see on the M2. Its cheap and the perceived value to new users is so much higher that a plain-jane bolt head. Its a pity our stock screws holes don't accept 1/4-20 threads...

http://www.mcmaster.com/#93228a150/=w6xk4i

http://www.mcmaster.com/#93228a150/=w6xk4i

Re: thread-locking insert for Z-stop screw

If you're never going back, they'll accept 1/4-20. The stock is M5 I believe, and 1/4-20 is a larger diameter than that, so you could drill + tap.BigBadBry wrote:ok, now THIS would have been an AWESOME stock part to see on the M2. Its cheap and the perceived value to new users is so much higher that a plain-jane bolt head. Its a pity our stock screws holes don't accept 1/4-20 threads...

http://www.mcmaster.com/#93228a150/=w6xk4i

Custom 3D printing for you or your business -- quote [at] pingring.org