Cleanliness and lubricity is the first thing you should look at.

First let's assume you were formerly printing fine.

1. Home the Z.

2. Disable the motors

3. What does your Z do?

- a. Nothin', just sits

b. Staaarts toooo droooopp reeeeaaalll slooooowww.

c. Falls quickly to the bottom within a couple seconds.

4. If your answer is anything other than c. then you need to clean and lube the screw.

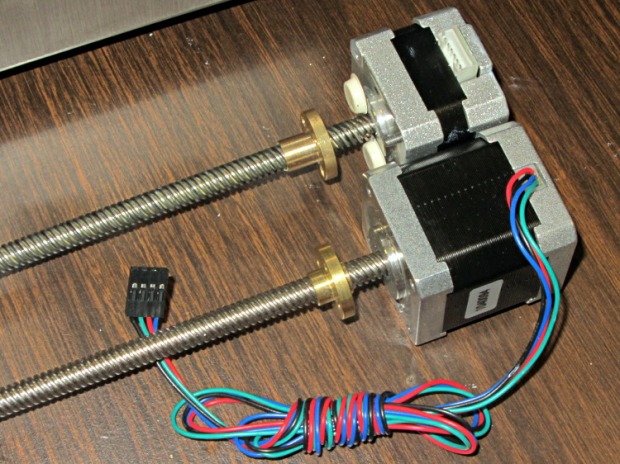

5. Wipe off the screw with a paper towel. Place a brass brush against the screw near the brass nut and home your Z while riding the brush up and then jog your Z back down and ride the brush down the screw from underneath. You may need to do this a few times to degunk the screw. Do NOT scrub or use abrasives to clean the screw. Hopefully the Z will start falling faster after a few of these cycles.

6. I apply about a thin pencil line of the grease along the screw and smear it in a bit. Then run the Z up and down under power and then see how it is dropping. You may need to apply lithium grease sparingly to flush out the old grease and repeat step five if it is slow in a spot.

7. You should be able to get back to printing now. If not, you may have alignment issues or electronic gremlins or unhappy steppers.

I have the small Z-motor and this has solved every Z-drop issue I have had until I notice that the build plate is starting to drop slowly again. I sometimes let it get too far, but it is easy enough to see the need for cleaning as it arises.

Maybe it will help out with your issue.